"SAC" Creep Data

Source and Plot

of Data

|

|

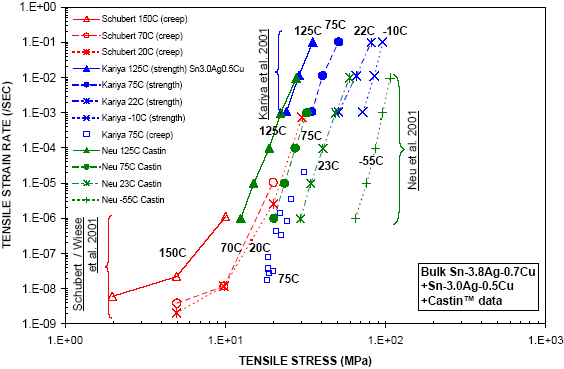

| Figure

23: Log-log plot of isothermal creep data for Sn-Ag-Cu

and Castin™ bulk solders.

Isothermal creep data from three independent sources are

plotted as tensile strain rate (/second) versus tensile stress

(MPa) in Figure 23. The data covers two orders of magnitude

on the stress axis and eight orders of magnitude on the strain

rate axis. Test temperatures are in the range -55°C to

150°C.

The original data, given in Table B.1, was digitized by

Kil-won Moon of NIST. The raw

data was obtained from the following figures in their respective

publications: |

|

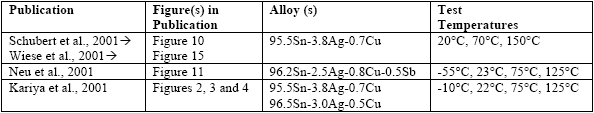

| Table 10:

Source of data, alloy composition and test temperatures.

These investigations of SAC properties are fairly recent,

when compared to the Sn-Pb or Sn-Ag literature, since it is

only recently that SAC alloys have received increased attention

from industry. |

|

Specimens |

|

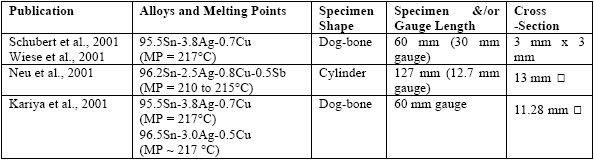

Table

11: Specimen Geometries (MP = Melting Point of Alloy). |

|

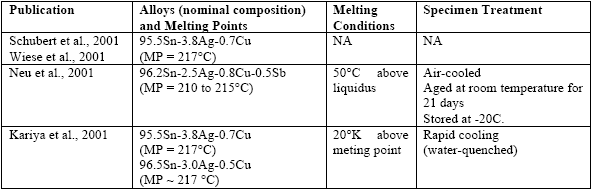

| Table

12: Melting Conditions and Specimen Treatments (NA

= not available).

Test specimens were dog-bone- or cylinder-shaped tensile

specimens with specimen and/or gauge length and cross-sectional

dimensions given in Table 11. Melting and cooling conditions

as well as thermal treatment of specimens, when available,

are summarized in Table 12. The reader is referred to the

original publications for additional details on the specimen

preparation.

The alloys have nominal compositions with elemental contents

in the following ranges:

- 95.5 to 96.5% wt. for Sn.

- 2.5 to 3.9 % wt. for Ag.

- 0.5 to 0.8% wt. for Cu.

- Chemical analysis of the 95.5Sn-3.8Ag-0.7Cu (nominal)

alloy studied by Schubert et al. gave a composition of 95.4%

wt. Sn, 3.91% wt. Ag and 0.71% wt. Cu (from Table 1 in Schubert

et al., 2001).

Comparing the specimen information from the three sources,

note that:

- The specimens by Schubert et al. have a significantly

smaller cross-section: 3 mm x 3 mm versus 11.28 mm and 13

mm in diameter for the specimens by Kariya et al. and Neu

et al., respectively.

|

| |

- The above dimensions compare to typical sizes of 0.1 to

0.2 mm (4 to 8 mils) for flip-chip solder joints, or 0.5

mm (20 mils) for Ball Grid Array (BGA) solder joints.

|

- The Kariya et al. specimens were rapidly cooled by water-quenching

while the Neu et al. specimens were air-cooled although

the cooling rate was not reported. The cooling conditions

for the Schubert et al. specimens were not reported.

Microstructures |

|

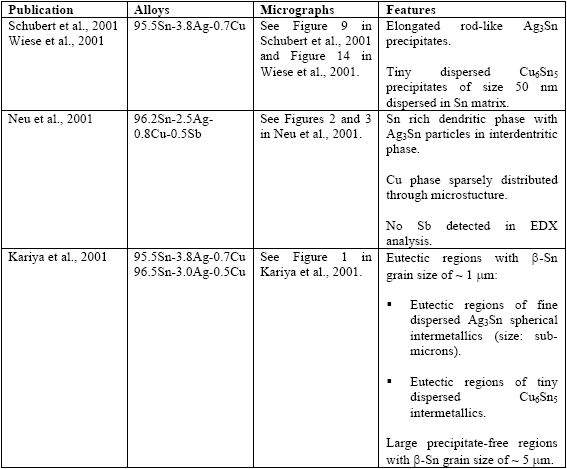

| Table

13: Microstructure of bulk "SAC" specimens.

The microstructure of the as-cast SAC solders consists of

the Sn matrix with precipitate-free b-Sn regions and eutectic

(or near-eutectic) regions having Ag3Sn or Cu6Sn5 intermetallic

phases dispersed in the Sn matrix. Specific microstructural

features for the alloys and specimens under study are given

in Table 13.

Test Procedures |

|

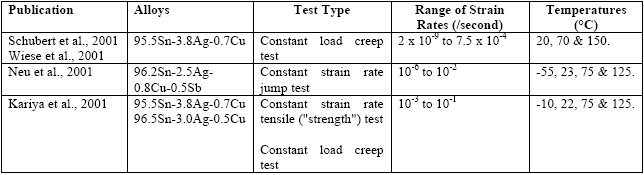

| Table

14: Test procedures and conditions.

The test conditions and procedures are summarized in Table

14. The isothermal tensile tests are of three

types:

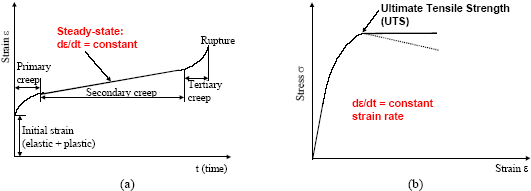

- Conventional "creep" tests (with constant load

rates) where the linear portion of the strain-versus-time

response gives the "minimum" or steady strain

rate (see Figure 24a).

- Conventional "strength" tests (stress / strain

tests ran at constant strain rates) where the maximum stress

gives the Ultimate Tensile Strength (UTS) of the specimen

at a given strain rate (Figure 24b). Once the UTS has been

reached, the typical response of solder is further elongation

of the specimen at constant stress or with a slow drop in

load.

- Strain rate jump tests which are similar to the above

stress / strain tests except that the strain rate was

increased by a factor of ten after each increment of 1.5%

strain.

|

|

| Figure

23: Output of (a) creep test; (b) "strength"

test.

Noteworthy observations about these tests are:

- In general, the first two types of tests give similar

strain-rate-vesus-stress equations since the strain rate

is constant during both the strength test and the steady-state

phase of the creep test. However, one of the limitations

of the creep tests is that they are not run at constant

stress since it is easier to control loads rather than stress.

The reported stress is the initial stress defined as the

applied load divided by the initial cross-section of the

specimen.

- As pointed out by Neu et al., 2001, the strain rate jump

tests allow for the acquisition of tensile strengths at

different strain rates from a single specimen. However,

Neu et al. mentionned that the strength results may be affected

by the history of prior deformations of a given specimen

when jumping from one strain rate to the next.

The reviewed literature focuses on steady-state creep.

To our knowledge, the other deformation modes, i.e. the initial,

instantaneous plastic flow and primary creep have not been

reported on for SAC-type alloys. Based on studies by Darveaux

et al. (1992, 1995), these deformation modes are not negligible

for neareutectic Sn-Pb and Sn-Ag alloys and are worthwhile

investigating further for SAC solders. |