| Other Properties

of Sn-3.5Ag

Young's Modulus vs. Temperature |

|

|

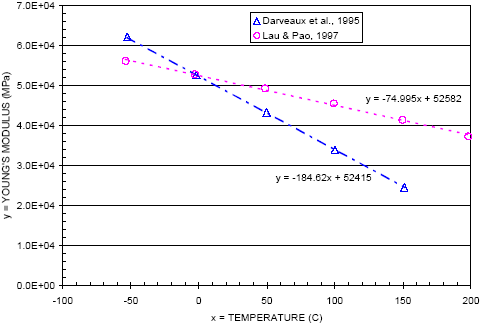

Figure

22: Plot of Sn3.5Ag Young's Modulus E (MPa) versus

temperature T (°K).

Young's modulus versus temperature is plotted in Figure

22, similar to Figure 9 in Wiese et al., 2001. The original

source of the data was publications by Darveaux et al. (1995)

and Lau & Pao (1997). The data was digitized and, for

each dataset, we added a linear trendline and its equation

so the temperature-dependence of Young's modulus is readily

available. The temperature-dependent Young's modulus is entered

as material properties in stress / strain analysis programs

such as FEA codes. Young's modulus is also used to scale steady-state

stresses in some creep rate models.

Poisson's Ratio

Another elastic property that is of use in stress/strain

analysis programs or to convert Young's modulus E to a shear

modulus, G, is Poisson's ratio. Lau et al. (2002) used a Poisson's

ratio n = 0.4 in the finite element modeling of Sn3.5Ag assemblies.

We were not able to locate any report with direct measurements

or experimental determination of Poisson's ratios for Sn3.5Ag

alloy.

Coefficients of Thermal Expansion

(CTE)

|

|

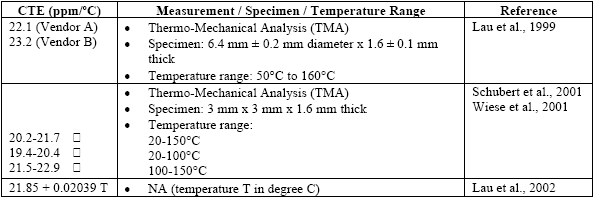

| Table

9: Sn3.5Ag CTE values.

Measured or quoted Coefficients of Thermal Expansion (CTEs)

for the Sn3.5Ag alloy are given in Table 9. As expected, the

CTE results show a slight temperature dependence. From the

data in Table 9, an overall average value for the CTE of Sn3.5Ag

is about 21.5 ppm/°C.

For comparison purposes, a value that is often quoted for

the CTE of eutectic SnPb is 24 ppm/°C. The CTE of Sn-3.5Ag

appears to be slightly lower than that of eutectic SnPb. This

is beneficial to solder joint reliability, in general, since

a lower CTE of the solder alloy reduces local CTE mismatches

between the solder joint and the interconnected parts.

Other Physical Properties

Other properties of interest for predictive modeling of

solder joint geometry using, for example, a computer program

such as Surface Evolver, are:

- Solder density,

in lb/in3 (or g/cm3).

in lb/in3 (or g/cm3).

|

| |

(g/cm3).

= 7.5 (NIST Boulder database). (g/cm3).

= 7.5 (NIST Boulder database). |

| |

|

- Note that an error seems to have propagated through the

literature since both the ITRI publication (No. 656) and

the GE / DeVore handbook quote

= 10.38 g/cm3 for Sn-3.5Ag.

= 10.38 g/cm3 for Sn-3.5Ag.

- The NIST-quoted value is consistent with the rule of

mixture calculation:

= 96.5%

= 96.5%  Sn

+ 3.5% Sn

+ 3.5%  Ag,

where the density of pure Sn and Ag are Ag,

where the density of pure Sn and Ag are  Sn

= 7.31 g/cm3 and Sn

= 7.31 g/cm3 and  Ag

= 10.5 g/cm3, gives: Ag

= 10.5 g/cm3, gives:  Sn-3.5Ag

= 7.42 g/cm3. Sn-3.5Ag

= 7.42 g/cm3.

|

| |

- Surface tension,

,

in units of mNm-1, to be specified in terms of

the soldering atmosphere (e.g., air, nitrogen…): ,

in units of mNm-1, to be specified in terms of

the soldering atmosphere (e.g., air, nitrogen…):

|

| |

|

= 431 mNm-1 in air, g = 493 mNm-1

in nitrogen (at 50°C above liquidus), after Glazer (1994)

& quoted in NIST-Boulder database.

= 431 mNm-1 in air, g = 493 mNm-1

in nitrogen (at 50°C above liquidus), after Glazer (1994)

& quoted in NIST-Boulder database. |

| |

- Thermal conductivity, k in units of W/m°K, is also

used for heat transfer analysis: NA.

|

|

Missing values or additional measurements of the above physical

properties will be added to the material property database

when the data is available. |

|