| Creep

and Constitutive Models for Near-Eutectic SnPb

Overview

One lesson learned from SnPb studies is that here is no unique

constitutive model for SMT solder joints, thus the variety

of models available throughout the literature. In the end,

the applicability of a given model to real life assemblies

and a reasonable agreement between the ensuing life predictions

and test results determine whether a constitutive model will

be of use to design engineers and reliability analysts.

The mechanical behavior of solder depends on the joint microstructure

and is affected by many parameters such as intermetallics,

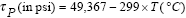

joint or specimen size, cooling rate of the assembly after

soldering, aging in service etc. Test factors such as specimen

or load eccentricity, temperature variations and measurement

errors also contribute to the scatter in the mechanical properties

of solder as is well known, for example, for steady state

creep. Nevertheless, simplified constitutive models have been

developed to help characterize the mechanical behavior of

SnPb solder and enable first-order stress/strain analysis

of solder joints using methods of classical mechanics or numerical

techniques such as the Finite Element Method (FEM).

What is Creep? |

| |

| Figure

1: Creep curve: strain versus time under constant

stress (or load) and temperature.

Under constant load or stress, solder undergoes progressive

inelastic deformations over time. This timedependent deformation

is called creep and the associated strains that develop over

time are creep strains. When the test specimen is subjected

to a constant load, the initial, instantaneous response includes

elastic and time-independent plastic flow. Creep then proceeds

in three stages of primary, secondary and tertiary creep (see

Figure 1). During primary creep, metals strain-harden. The

strain rate decreases over time, as hardening of the metal

becomes more difficult. Specimen deformations keep increasing

with secondary creep proceeding at a steady strain rate. Note

also that the initial deformation that occurs upon loading

of the test specimen includes both elastic and plastic strains.

Often, these initial deformations are not reported on in the

context of creep studies. However, they cannot be neglected,

a priori, because of the inelastic nature of the initial plastic

flow. Moreover, these initial deformations, which depend on

the loading rate, may become important under service conditions

with intermediate to rapid temperature ramps.

For most metals, secondary creep is the dominant deformation

mode at temperatures above half the melting point, TM , in

degree Kelvin. For eutectic SnPb, TM is 183°C =

456°K and 1/2 TM = 228°K = - 45°C.

That is, standard SnPb solder readily creeps at, and well

below, room temperature. The last stage of deformation is

tertiary creep where strain rates increase rapidly until the

test specimen ruptures. In SnPb solder, tertiary creep proceeds

by void formation and growth along grain boundaries, micro-cracking

and necking of tensile specimens.

Numerous researchers have investigated the mechanical and

creep behavior of near-eutectic SnPb solder (e.g., Baker

et al., 1973, Chen et al., 1971, Darveaux

et al., 1995, Grivas et al., 1979, Hacke

et al., 1993, Kashyap, 1981, Knecht et al.,

1991, Pao et al., 1992, Shine et al.,

1988, Stone et al., 1985/94, Wong et al.,

1988/90). Most investigations have focused on steady-state

creep, with the secondary creep rate often given as a function

of stress and the absolute temperature, T: |

| |

(1) |

| special definitions: |

| |

|

secondary creep rate |

|

| |

A |

a material constant |

|

| |

b |

dislocation characteristic length or magnitude of Burgers

vector |

|

| |

g |

the material's grain size |

|

| |

T |

temperature |

|

| |

E(T) |

the temperature dependent Young’s modulus |

|

| |

k |

is Boltzman’s constant |

|

| |

|

stress |

|

| |

p and n |

constant exponents |

|

| |

Q |

the activation energy of the rate controlling diffusion mechanism |

|

|

Equation (1) is known as Dorn’s equation (Bird et al.,

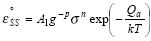

1969) and is often simplified as: |

|

(2) |

| special definitions: |

| |

A1 |

another material constant |

|

| |

Qa |

an apparent activation energy |

|

|

Equation (2) shows the strong dependence of creep rates on

stress and temperature as well as grain size (in the case

of SnPb solder).

Since creep properties, as well as strength and other mechanical

properties, vary with specimen size, the mechanical response

of tiny solder joints differs from that of bulk solder test

specimens. For engineering applications dealing with surface-mount

(SM) assemblies, constitutive models developed from measurements

on solder joint specimens have proven to be very useful. Solder

deformations, including creep, have been measured on solder

joints of actual electronic assemblies (e.g., Shine and Fox,

1988, Knecht and Fox, 1991) and for several solder alloys:

60Sn-40Pb, 62Sn-36Pb-2Ag, 96.5Sn-3.5Ag,

97.5Pb-2.5Sn, 100In and 50In-50Pb

(Darveaux et al., 1995). These models are presented, briefly,

hereafter because they have been found to be of use to practicing

engineers. The reader is referred to the original publications

for additional details as well as for relevant information

on the experimental techniques that were used and that could

be applied to the study of lead-free solders.

Motorola / Darveaux's Constitutive

Model

Darveaux and his co-workers at Motorola (Darveaux et al.,

1995) conducted extensive mechanical testing of flip-chip

and Ball Grid Array (BGA) solder joints and characterized

the time-independent plastic flow and creep deformations of

several solder alloys. Their constitutive model is described

below for several alloys of electronic solder. Robert Darveaux

implemented this model into two commercial finite element

codes, ANSYSTM and ABAQUSTM. His original

publication (Darveaux et al., 1995, Chapter 13 in Ball Grid

Array Technology) includes detailed recommendations on how

to input material constants in the preprocessor of those two

programs. One important feature of Darveaux’s creep

model is that it was found to apply consistently to several

solder alloys: 60Sn-40Pb, 62Sn-36Pb-2Ag,

96.5Sn-3.5Ag, 97.5Pb-2.5Sn, 100In

and 50In-50Pb, and over a wide range of temperatures

and several orders of magnitude in strain rates.

The initial, instantaneous strain that develops at the start

of a creep test includes an elastic strain and an inelastic

strain that represents time-independent plastic flow. The

plastic strain is described by a plastic flow or strain hardening

law of the form: |

|

(3) |

| special definitions: |

| |

|

plastic strain |

|

| |

C6 and m |

material constants |

|

| |

|

applied stress |

|

| |

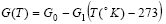

G=G(T) |

temperature-dependent shear modulus

given as: |

|

|

(4) |

| |

G0 |

shear modulus at 0°C |

|

| |

G1 |

shear modulus temperature coefficient |

|

| |

|

G0 = 1.9 Mpsi and G1

= 8.1 kpsi/°K for both alloys of 60Sn-40Pb

and 62Sn-36Pb-2Ag |

|

|

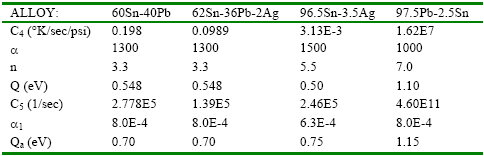

The elastic constants and the plastic flow parameters for

several solder alloys, including SnAg eutectic, are given

in Table 1 below. Note that the elastic constants and the

power-law exponent m are about the same for 60Sn-40Pb

and 62Sn-36Pb-2Ag. However, the constant C6

is about twice as low for 62Sn-36Pb-2Ag. Under

equal loads, tin-lead with 2% silver will see half as much

initial plastic strain than 60Sn-40Pb.

|

|

| Table 1:

Solder material constants for shear modulus and plastic flow

rule (after Darveaux et al., 1995).

During primary or transient creep, the creep strain is given

by the equation: |

|

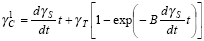

(5) |

| special definitions: |

| |

|

primary creep strain |

|

| |

|

transient creep strain |

|

| |

B |

transient creep coefficient |

|

| |

|

steady state creep

rate |

|

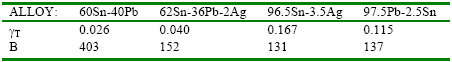

The primary creep constants for several alloys are given

in Table 2.

|

|

Table 2:

Primary creep constants for common solder alloys (after Darveaux

et al., 1995).

The primary creep rate is: |

| |

(6) |

Initially, at time t = 0, the primary creep rate is a factor

times greater than the steady state creep rate. For 60Sn-40Pb,

this factor is:

times greater than the steady state creep rate. For 60Sn-40Pb,

this factor is:  = 1 + 0.026 x 403 = 11.48, i.e., the initial transient creep

rate is over an order of magnitude higher than the steady

creep rate. For Sn-3.5Ag, the rate factor is even larger:

= 1 + 0.026 x 403 = 11.48, i.e., the initial transient creep

rate is over an order of magnitude higher than the steady

creep rate. For Sn-3.5Ag, the rate factor is even larger:

= 1 + 0.167 x 131 = 21.88. Thus, primary creep may not

be negligible in applications with high temperature ramp rate

or under thermal cycling conditions with short dwell times.

= 1 + 0.167 x 131 = 21.88. Thus, primary creep may not

be negligible in applications with high temperature ramp rate

or under thermal cycling conditions with short dwell times.

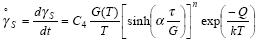

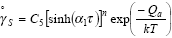

More general relationships were found to apply to steady

state creep of solder in shear: |

|

(7) |

| or in a simplified form: |

|

(8) |

| special definitions: |

| |

|

steady state strain rate |

|

| |

G(T) |

temperature-dependent shear modulus |

|

| |

T |

absolute temperature (in degree Kelvin) |

|

| |

|

applied stress |

|

| |

n |

constant exponent that depends on

the controlling creep mechanism |

|

| |

k |

Boltzmann’s constant (k = 8.620

x 10-5 eV/°K) |

|

| |

Q |

creep activation energy |

|

| |

Qa |

apparent activation energy |

|

| |

,

C4, C5 ,

C4, C5 |

constants |

|

The above constants and activation energies are given for

several solder alloys in Table 3.

|

|

Table 3: Steady state creep parameters

for common solders (after Darveaux et al., 1995).

DEC's Model

Knecht, Fox and Shine of the Digital Equipment

Corporation (DEC) conducted isothermal mechanical and fatigue

testing of 63Sn-37Pb solder joints on a 7.6 m x 7.6 mm,16

I/O Leadless Ceramic Chip Carrier (LCCC) test vehicle (Shine

et al., 1988, Knecht et al., 1991). The LCCCs were mounted

on stainless steel or G-10 organic substrates with copper

pads matching the component terminations (0.64 x 1.0 mm

pads). Solder joint thickness varied from 4 to 12 mil. Testing

was conducted at temperatures of 25°C, 60°C and

100°C. The solder joints were subjected to shear in

a torsion apparatus powered by an electric motor. Shear

deformations were determined from the reflection of a laser

beam on the mirrored edges of LCCC components. Creep data

was obtained from curves of isothermal creep strain versus

time under constant applied torques. Stable stress/strain

hysteresis loops were obtained from the first cycles of

fatigue tests conducted under constant plastic strain range.

From these experiments, and associated data reduction, failure

mode analysis and modeling, Shine and Fox (Shine et al.,

1988) concluded the following:

|

| |

- Grain boundary creep at low stresses and creep rates.

- Matrix creep at high stresses and creep rates.

|

- Solder joints undergo creep-fatigue failures associated

with steady-state creep. Creep damage occurs by a combination

of grain-boundary and matrix creep, with Scanning Electron

Microscope (SEM) photos of fatigued solder joints showing

intercrystalline voids and cracks. Isothermal fatigue life

cycles have an inverse relationship to integrated matrix

creep.

- The grain size of thick joints is larger than that of

thin joints and solder grain size increases during fatigue

testing. Under identical loads, thin joints with initially

smaller grain sizes are expected to have a longer fatigue

life than thick joints with larger grains.

Using the hysteresis loops and creep data from the above

experiments, Knecht and Fox (Knecht et al., 1991) developed

a simple constitutive model for eutectic (63Sn-37Pb)

solder in shear. The constitutive equations from that study

are summarized hereafter with some minor modifications. Knecht

and Fox used their model to conduct finite element analysis

of solder joints in SMT assemblies and to correlate fatigue

life data to integrated matrix creep strains.

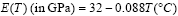

The average shear strain is given as the sum of an elastic

strain, a time-independent plastic strain, and

a secondary creep strain, that is: |

|

(9) |

| special definitions: |

| |

|

shear strain |

|

| |

|

elastic strain |

|

| |

|

time-independent plastic strain |

|

| |

|

secondary creep strain |

|

The elastic strain component is: |

|

(10) |

where the temperature dependent shear modulus is: |

|

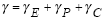

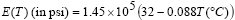

(11) |

Poisson's ratio for near-eutectic solder is  =

0.4 and the temperature-dependent Young's modulus is: =

0.4 and the temperature-dependent Young's modulus is: |

|

(12a) |

| or: |

|

(12b) |

The time-independent plastic strain is given by the following

plastic flow rule: |

|

(13) |

| special definitions: |

| |

|

temperature-dependent plasticity

parameter |

|

where the temperature-dependent plasticity parameter is obtained

by curve-fitting the plasticity parameter versus temperature

data in the original publication by Knecht and Fox (1991),

i.e.: |

|

(14) |

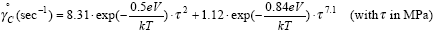

Finally, creep strains are obtained by integration of the

steady state creep rate equations: |

|

(15) |

| or |

|

(16) |

The first term on the right-hand-side of equations (15) and

(16) is for grain boundary creep with a stress exponent: nGB

= 2 and an activation energy:  HGB

= 0.5eV. The second term on the right-hand-side of

(15) and (16) is for matrix creep with a stress exponent:

nMC = 7.1 and an activation energy: HGB

= 0.5eV. The second term on the right-hand-side of

(15) and (16) is for matrix creep with a stress exponent:

nMC = 7.1 and an activation energy:

HGB

= 0.84eV. As shown by Knecht and Fox, these values

of stress exponents and activation energies are consistent

with steady state creep parameters reported in the literature

(see Table 4 below). HGB

= 0.84eV. As shown by Knecht and Fox, these values

of stress exponents and activation energies are consistent

with steady state creep parameters reported in the literature

(see Table 4 below).

|

| |

Table 4: Comparison of near-eutectic SnPb

creep parameters (after Knecht et al., 1988).

Last, note that, even though the experimental

results of Shine and Fox (Shine et al., 1988) suggest a

grain size effect, the constitutive model developed by Knecht

and Fox does not include any grain size parameter. The most

likely reason for this is that those effects are difficult

to quantify when the grain size is not a control parameter

of an experiment. However, Knecht and Fox stated that "using

"real" joints will generate practical results"

(Knecht et al., 1991) and their constitutive model is thought

to be useful for the engineering analysis of solder joints.

|

| Hughes' Creep

Model |

|

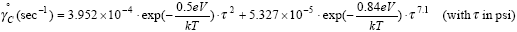

Figure 2: Creep rate plot for Pb/Sn eutectic

solder.

Boon Wong and his colleagues at Hughes Aircraft

Company (B. Wong et al., 1988) compiled Sn-Pb eutectic steady

state creep data from seven sources. The data, which covered

several orders of magnitude in stress and creep rates, was

found to fit in a correlation band as shown in Figure 2.

The raw data fell within a band of height about one order

of magnitude in the vertical direction. The width and height

of the band are typical of the scatter usually associated

with creep data. Available data points from Shine and Fox

(Shine et al., 1987) are found to fit within or close to

Wong's correlation band. In Figure 2, the normal stress,

sSS, is scaled with a temperature-dependent Young's modulus,

E = E(T), on the horizontal axis. Young's modulus is given

as in equation (12a). The steady state creep rate on the

vertical axis is normalized with a Arrhenius-type, temperature-dependent

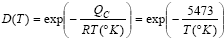

diffusion parameter, D = D(T):

|

|

(17) |

| special definitions: |

| |

QC |

average activation energy for

creep of eutectic SnPb solder: QC = 45 kJ/mole

= 0.47eV |

| |

R |

universal gas constant: R

= 8.314 J/°K.mole. |

|

The correlation band in Figure 2 has two distinct slopes

that reflect different creep mechanisms:

- A dislocation glide regime with a stress exponent of 3

in the low stress region.

- A dislocation climb regime with a stress exponent of 7

in the higher stress region.

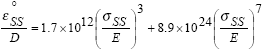

Based on the above correlation of creep data, Wong gave the

following expression for average creep rates: |

|

(18) |

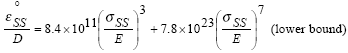

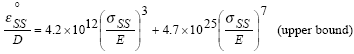

The equations of the lower and upper bounds of the correlation

band are (Clech et al., 1988): |

|

(19) |

|

(20) |

The above stress exponents are consistent with the steady

state creep equation in DEC's steady state creep model. Note

also that Wong's creep rate equations do not include grain

size dependence either. Wong argued that the experimental

data was inconclusive at the time (Wong et al., 1988) and

this did not warrant any attempt at including grain size effects.

Wong also stated that grain size dependence is not expected

in either the climb or glide-controlled creep regimes. One

last important aspect of Wong's steady state creep model is

that it was derived based on the correlation of creep data

from several independent sources, with the correlation holding

over a wide range of temperatures (-60°C to 150°C),

stresses and creep rates.

The above compilation of creep data has been used successfully

in a solder joint life prediction model developed by Wong

et al., 1988. The upper bound of the correlation band was

also used as the creep rate equation in the Solder Reliability

Solutions (SRS) life prediction model (Clech, 1996). The upper

bound was selected in order to maximize strain rates, thus

building in some conservatism in the model. The SRS model

has since been validated by over sixty experiments (Clech,

2000).

Based on Sn-Pb experience, we can expect creep rates from

compiled test results for lead-free solders to spread over

one order of magnitude. Such spread in the data did not impede

the development of useful, first-order solder joint life prediction

models for Sn-Pb assemblies.

Hall's Stress / Strain Hysteresis

Loop

One of the most significant contributions to the field of

solder joint mechanics, and also most enjoyable reading (in

this author’s opinion), is the shear strain and hysteresis

loop measurements and theory developed by Peter Hall at AT&T

Bell Laboratories (Hall, 1984 and 1991). Using strain gauge

measurements and a simplified analysis of shear forces exerted

on the solder joints of LCCC assemblies, Hall showed that

the stress/strain response of solder joints during temperature

cycling is a hysteresis loop (see Figure 2). The shape of

the loop reflects the temperature-dependent inelastic deformations

of solder and elastic deformations of the entire assembly.

The thermal expansion mismatch between board and component

is accommodated by shear of the solder joints and simultaneous

stretching and bending of the board and component. These elastic

deformations of the interconnected parts provide compliance

to the assembly, suggesting practical ways to reduce solder

joint stresses by designing boards and components that are

more compliant.

|

|

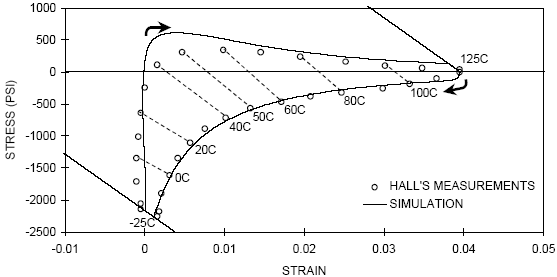

Figure 3: Solder joint hysteresis loop

during thermal cycling between -25°C and 125°C.

The hysteresis loop in Figure 3 illustrates

the complexity of the solder joint stress/strain response

during a large temperature cycle between -25°C and 125°C.

The dwell times at the temperature extremes were two hours.

The ramp times were five hours with a rather slow ramp rate

of 0.5°C/minute. The data points, shown as circles,

are derived from Hall's strain measurements on non-castellated,

25-mil pitch, 84 I/O LCCCs mounted on FR-4. The solder joints

were 11 mil high. A complete description of test vehicles

and details of the experimental set-up, measurement techniques

and data reduction procedures are given in Hall's publications

(Hall, 1984, 1987, 1991). Pao conducted similar measurements

on a double-beam, alumina on aluminum test vehicle (Pao

et al., 1987).

The shape of the hysteresis loop in Figure

3 reflects the non-linear, temperature-dependent constitutive

behavior of solder. Important features of the loop are described

hereafter:

-

The loop is described clock-wise. Isothermal

stress reduction lines are drawn as dashed lines between

the data points corresponding to equal temperatures during

the ramp-up and ramp-down phases of the thermal cycle.

The stress reduction lines are shown for every 10 or 20°C

temperature increment. The stress reduction lines are

almost parallel to each other, with an average slope in

very good agreement with the slope predicted by Hall’s

assembly stiffness model.

- During the dwell periods at the temperature extremes,

stresses are reduced along the stress-reduction lines (shown

as solid lines) for those temperatures:

|

| |

- At 125°C, where solder is very soft, shear strains

are large and initial stresses are relatively low, less

than 200 psi. Creep rates are very high and stress reduction

is rapid. The intersect of the stress reduction line with

the strain axis is the maximum available strain due the

thermal expansion mismatch between the board and the LCCC

component.

- At -25°C, initial stresses are much higher, of the

order of -2300 psi. In spite of high stresses, there is

not much stress reduction during the two-hour dwell because

creep rates are rather small at cold temperatures.

|

- During the ramp-up phase of the thermal cycle:

|

| |

- As temperature goes up, starting at -25°C, solder

is relatively strong and the shear strain remains about

constant. Actually, shear forces are unloaded almost elastically.

- Past about 35°C, where the shear force is zero, stresses

build up due to plastic flow of solder in the opposite direction

and strains start increasing with the added thermal expansion

mismatch between board and component.

- Creep accelerates as temperature keeps going up. Slightly

past 50°C, the creep rates are so high that stress reduction

prevents any further build-up of stress. Creep strains develop

at a faster rate, contributing to rapid increments in the

total shear strain.

- When temperature approaches 125°C, strains keep increasing

with the thermal expansion mismatch between board and component

and stresses relax at a rather fast rate.

|

- During the ramp-down phase of the thermal cycle:

|

| |

- As temperature goes down, starting at 125°C, the

cycle is reversed and shear strains decrease.

- Initially, and down to about 50-60°C, shear strains

decrease at a high rate. Stresses start building up in the

opposite direction.

- From 50-60°C to -25°C, stresses become larger

and built up at faster rate since solder becomes stronger

at lower temperatures.

|

| The simulated loop shown in Figure

3 was generated using the plastic flow rule and creep constitutive

model from DEC. Loop simulations have been conducted by several

investigators using slightly different approaches and constitutive

models (e.g., Sherry and Hall, 1986, Clech et al., 1987, Lovasco,

1988, Subrahmanyan et al., 1989, Wilcox et al., 1989, Li et

al., 1991, Whalley et al., 1989/91, Lau and Pao, 1997). |

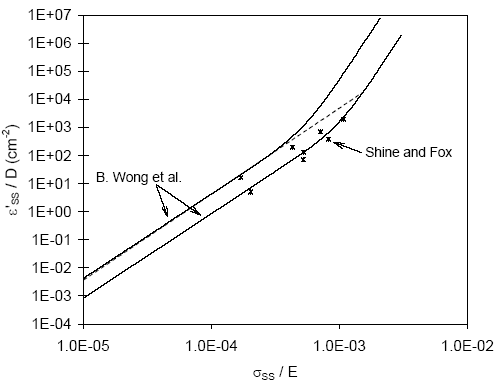

|

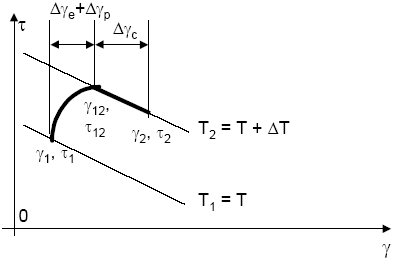

Figure 4:

Solder joint stress/strain simulation when temperature increases

from T to (T +  T). T).

The basic algorithm that is used to generate stress/strain

hysteresis loops during thermal cycling follows the stress/strain

curves shown in Figure 4. During a small time-step from time

t to (t +  t),

temperature increases from T to (T + t),

temperature increases from T to (T +  T).

At time t, the stress/strain curve intersects the stress reduction

line for temperature T1 = T. Due to the increase

in temperature, stresses build-up instantaneously from T).

At time t, the stress/strain curve intersects the stress reduction

line for temperature T1 = T. Due to the increase

in temperature, stresses build-up instantaneously from  1

to 1

to  12

with a change in strain from 12

with a change in strain from  1

to 1

to  12

that includes an elastic strain increment 12

that includes an elastic strain increment   e

and plastic flow with a strain increment e

and plastic flow with a strain increment   p.

Stresses then relax from p.

Stresses then relax from  12

to 12

to  2,

and the shear strain increases by creep (increment 2,

and the shear strain increases by creep (increment   c)

along the stress reduction line at temperature T2

= (T + c)

along the stress reduction line at temperature T2

= (T +  T).

Knowing the stress / strain state ( T).

Knowing the stress / strain state ( 1, 1,

1)

at time t, the stress / strain state ( 1)

at time t, the stress / strain state ( 2, 2,

2)

at time (t + 2)

at time (t +  t)

is obtained by solving the following system of four equations

with four unknowns t)

is obtained by solving the following system of four equations

with four unknowns  12, 12,

12, 12,

2,

and 2,

and  2: 2:

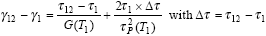

- From the stress reduction line at T2 = (T +

T): T):

|

|

(21) |

|

(22) |

|

- For the strain increment due to elastic deformation and

plastic flow as per, for example, DEC's plastic flow rule:

|

|

(23) |

|

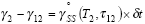

- For the creep strain developing during the short dwell

of duration

t

at T2: t

at T2:

|

|

(24) |

| special definition: |

| |

|

steady state creep

rate under an applied stress  12

at temperature T2 12

at temperature T2 |

The above algorithm can be implemented in a computer program

or even in a spreadsheet. Usually, a zero stress / strain

state is used, somewhat arbitrarily, to initialize the algorithm.

Small enough time steps are required to follow the prescribed

temperature profile closely and to generate the stress / strain

response with the desired accuracy. A few cycle iterations

are typically required to obtain a closed and stable hysteresis

loops for stiff systems like leadless assemblies. Many more

iterations are needed for compliant systems like leaded assemblies

with very compliant leads. Hysteresis loops can also be obtained

using finite element models that include material options

for a constitutive model with elastic, plastic flow and creep

(see, for example, Darveaux et al., 1995/97, Lau and Pao,

1997). |

|