|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

Electrodeposited Copper for On-chip Interconnects:

|

|

|

|

Tools for the Microelectronics Industry

|

|

|

|

The introduction of copper metallization and low dielectric constant materials into chip manufacture is the most difficult

interconnect challenge of modern microelectronics.Current state-of-the-art chips have interconnects, or on-chip "wiring," as narrow as 150 nm

to 180 nm with height to width ratios as great as 2:1. The filling of such trenches with copper can currently be accomplished by

electrodeposition, but roadmaps for the semiconductor industry state needs for trenches as narrow as 50 nm with a 10:1 aspect ratio.

Researchers at NIST are providing the fundamental understanding required to achieve these goals. Models of the mechanism

behind superfilling during copper electrodeposition, and associated computational and measurement tools developed at NIST are

addressing the needs of the microelectronics community and are already in use by industry to streamline the development of

electrodeposition baths.

|

|

|

|

|

The semiconductor industry has recently shifted from the use

of aluminum for interconnects, or on-chip "wiring," in

integrated circuits to copper because of its lower resistivity and

higher electromigration resistance. Electrodeposition has been found

to be the best means to deposit copper into the narrow,

deep trenches used for circuitry, since "superconformal" deposition

is possible which fills very narrow trenches without porosity.

An electrolytic copper linewidth of 180 nm is now

commonly found in IC fabrication. Extension to the narrower and

deeper lines needed in the next generation of IC requires

industrial development of new electrolytes and deposition schemes.

Development of plating baths able to deposit in trenches

with aspect ratios (height/width) as high as 10:1 is limited by

the necessity of time-consuming, resource-intensive evaluations

with actual nano-scale patterned substrates. Such experiments

require microstructural characterization by focused ion beam

(FIB), scanning electron microscopy (SEM) and transmission

electron microscopy (TEM) on an individual basis.

NIST efforts address metrology needed for

superconformal deposition that minimizes this time-consuming

experimental work. The mechanism responsible for superconformal

electrodeposition of copper in high aspect ratio features has

been determined. Simulations from a model based on this

mechanism have been shown to predict results of electrodeposition

filling experiments in trenches as small as »90 nm wide and

»450 nm deep. No fitting parameters are required to model this behavior.

This work has built upon two recent Metallurgy

Division discoveries. First, an electrolyte was developed that

yields superconformal electrodeposition of copper. Second,

voltage cycling-induced hysteresis of copper deposition rate on

flat copper specimens was shown to be indicative of the ability of

an electrolyte to yield superconformal deposition.

Superconformal deposition was shown to occur only when both an

inhibiting additive and an accelerating additive are present in the electrolyte.

Kinetic parameters for particular electrolytes are obtained

from the cyclic voltammetry described above. These kinetic

parameters describe the rate at which the accelerating additive accumulates

on the copper surface, displacing the inhibiting additive that

retards local copper deposition. They also quantify the impact

this accumulation has on the local copper deposition rate.

The NIST Curvature Enhanced Accelerator Coverage

(CEAC) model of superconformal electrodeposition uses these

parameters to predict filling of features. Most importantly, this

model recognizes changes of local coverage of accelerator on the

interface both by accumulation from the electrolyte and by changes of

the local area upon which the accelerator has adsorbed.

Accumulation of accelerator at the bottom of superfilling trenches is

dominated by this geometrical effect. Accelerator coverage on the bottoms

of

|

|

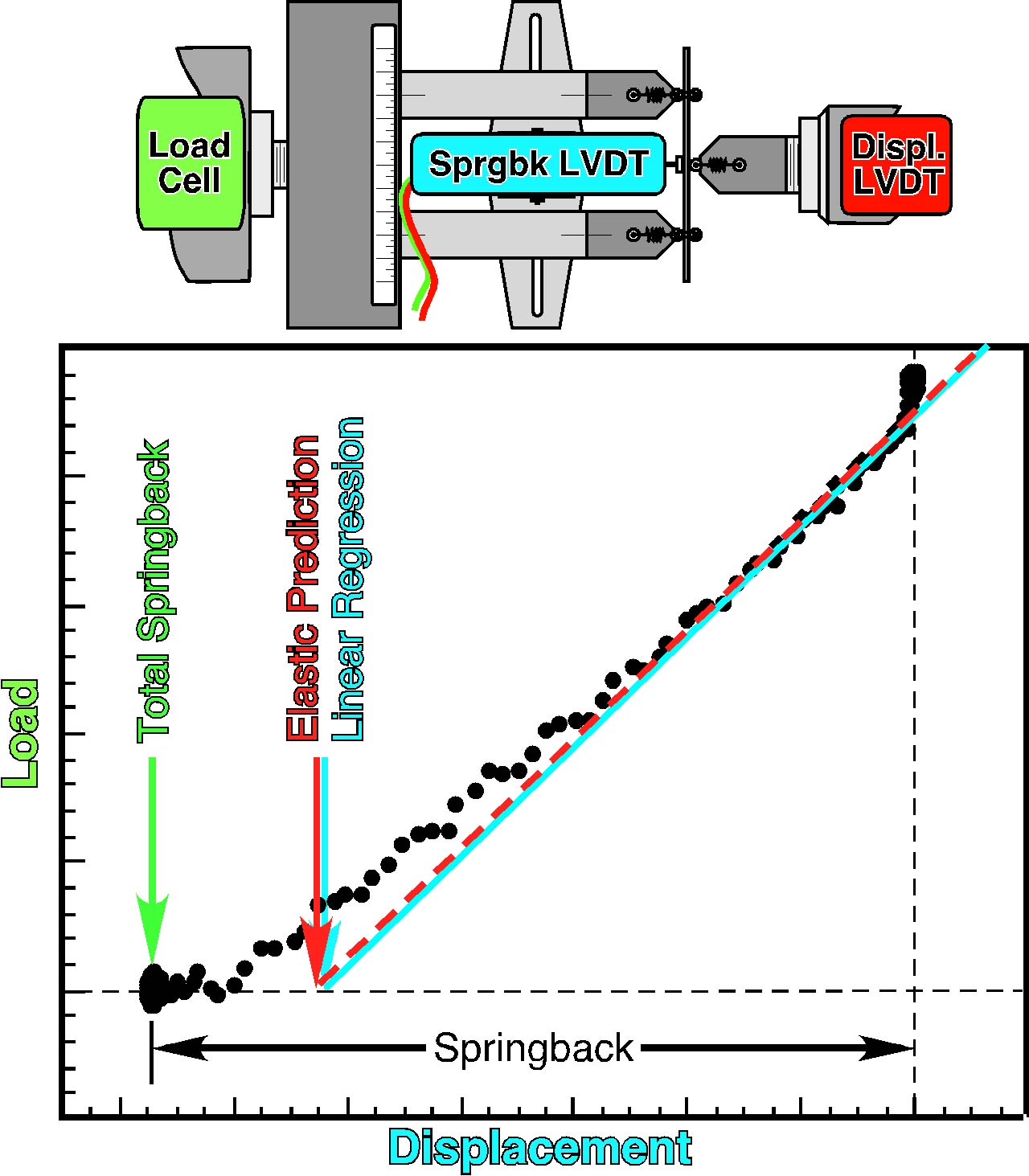

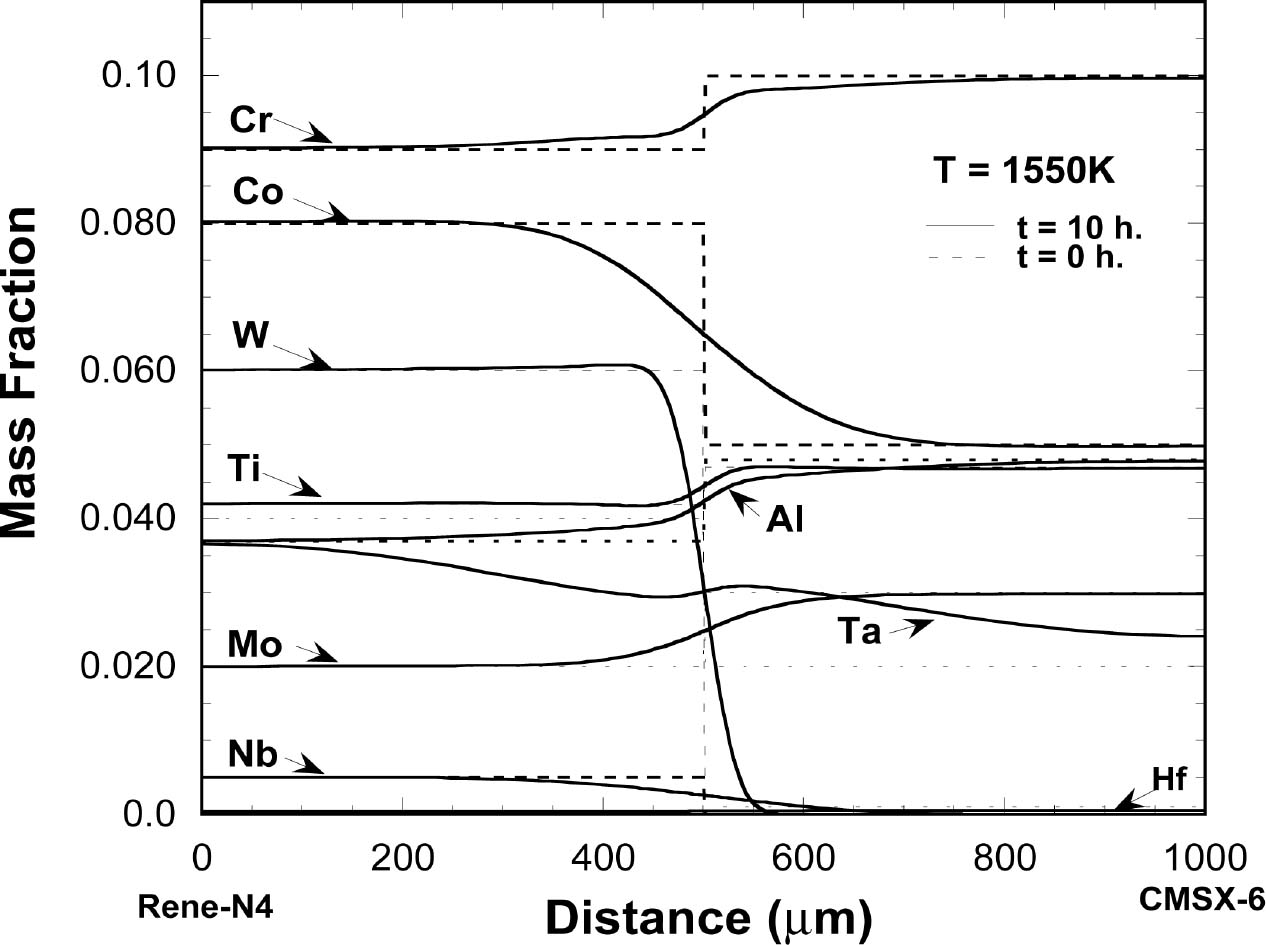

Figure 1. (top) Experimental current-voltage curves

for copper deposition on a flat copper substrate in

electrolytes containing a deposition inhibiting additive plus

varying amounts of an accelerating additive. Note the

hysteresis and the saturation at high concentrations. (bottom) Fit

of accelerator accumulation used to extract kinetic

parameters for the Curvature Enhanced Accelerator

Coverage (CEAC) model of superfill.

fine features thus increases as the surface area decreases

during copper deposition. This, in turn, accelerates copper deposition.

The positive feedback cycle results in filling of the trench

from the bottom upward, i.e., superconformal deposition. The

finer the feature, the more important area change can be - it requires

an appropriately designed electrolyte composition and

appropriate deposition conditions to take full advantage of this effect.

This research, largely conducted in the past two years,

has already resulted in accomplishments and impacts of

consequence to the microelectronics industry. These include:

• Explained the significance for superconformal deposition

of hysteresis in deposition on flat copper substrates.

• Showed how the hysteretic behavior can be modeled to

extract kinetic parameters describing the rate and impact

of additive accumulation on the copper/electrolyte

interface. (Figure 1.) |

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

.jpg)

.jpg)

Figure 2 (Left side) Superfill results for

accelerator concentrations of (0, 0.5, 5 and 40) µmol/L (top to bottom).

A window for superfill exists around 5 µmol/L

concentration. (Right side) Predictions of the newest computer code for

the three finest features at (0.5 and 5) µmol/L (top and

bottom). Inclusion of diffusional effects results in voids

indicating failure to fill. Simplifications in the first NIST model

of superfill resulted in seams in features that failed to fill.

• Developed the Curvature Enhanced Accelerator

Coverage (CEAC) model that explains how accumulation

of accelerator is impacted by changing area at the bottoms

of fine features and how this effect causes

superconformal deposition.

• Developed computer codes to predict superfilling of

fine features using only the results of cyclic

voltammetry studies with flat copper substrates. The most recent

of these codes describes diffusion of the cupric ion

and accelerator through the electrolyte, interface

kinetics affecting transfer onto the copper/electrolyte

interface, motion of the interface, and the impact of interfacial

area change on accelerator concentration and local

copper deposition rate.

This information has been conveyed to U.S. industry,

academia and other national laboratories through eight presentations

given in professional society meetings attended by industry

representatives from electrolyte suppliers, analytical tool, plating

tool and chip manufacturing industries.

|

|

|

|

|

For More Information

On This Topic:

|

|

D. Josell, D. Wheeler, W. H. Huber, and T. P. Moffat, "Superconformal

Electrodeposition in Submicron Features," Phys. Rev. Lett.

87, 016102 (2001).

T. P. Moffat, D. Wheeler, W. H. Huber, and D. Josell, "Superconformal

Electrodeposition of Copper," Electrochem. and Solid-State Lett.

4, (4) C26 (2001).

T. P. Moffat, D. Josell, and Daniel Wheeler

|

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

High Temperature Lead-Free Solders:

Tools for the Microelectronics Industry

|

|

|

|

Increasing global concern about the environment is bringing regulatory and consumer pressure on the electronics industry

in Europe and Japan to reduce or completely eliminate the use of lead in most products. Worldwide, the microelectronics industry

has made great progress toward application of lead-free solders in the relatively benign conditions of consumer electronics. In 2001,

the National Center for Manufacturing Sciences (NCMS) completed the High Temperature Fatigue Resistant Solder Project to

address the industrial need for lead-free solders in harsh environments, such as encountered in automotive under-the-hood

applications. NIST played a leadership role in this research project, chairing the alloy task group and providing definitive, timely materials

data and critical analyses needed for evaluating candidate solders, leading to the development of new lead-free solders with

excellent performance, outperforming industry-standard compositions.

|

|

|

|

|

Microelectronics assembly has, from its infancy, been based

on tin-lead eutectic solder, a mixture of tin and lead that melts

at 183 °C. In recent years there has been an increasing need

within the avionics, telecommunications, oil exploration, and

automotive industries for solders which perform reliably at

ever-higher temperatures, temperatures which approach the melting point

of tin-lead eutectic. Such harsh environment applications

require solders with melting points higher than that of tin-lead

eutectic in order to achieve the required reliability. In addition,

recent legislative and marketing pressures in Europe and Japan

have pushed U.S. manufacturers to pursue lead-free solders for

all microelectronics applications, leading to the double challenge

of developing high temperature, Pb-free solders.

In 1996, the National Center for Manufacturing

Sciences (NCMS) initiated the High Temperature Fatigue Resistant

Solder Project to address the need for high temperature, high

reliability solders in response to a need identified and defined by a

number of companies in the microelectronics, automotive, avionics

and telecommunications industries.

The resulting consortium, consisting of eight industrial

corporations, academia and NIST, has completed its four-year program.

Consortium members include Allied Signal, Amkor

Technologies, Delphi Delco Electronics Systems, Ford Motor

Company, Heraeus Corporation, Indium Corporation, Johnson

Manufacturing, Rockwell International Corporation, Iowa State

University, and NIST. The goal of the project was to

determine whether highly reliable, nontoxic, cost-effective substitutes

could be found for high lead and Sn-Ag eutectic solders in

harsh environments.This goal required gaining extensive knowledge

of the properties and manufacturability of alternative solder alloys.

The project members initially identified about 200

candidate solder compositions. Experimental measurements on 52 of

the alloys were made to characterize melting and wetting

behavior and reactions with substrates during prolonged exposure at

high temperature. A thermal-fatigue screening test was run on 12

of the most promising Pb-free alloys. From these candidates,

7 alloys were chosen for full scale manufacturing and

reliability trials, utilizing a variety of surface mount components cycled

up to 160 °C.

The project was divided into two major task groups _ the

Alloy Selection and Characterization Group and the Testing Group.

In addition to chairing the Alloy Task Group throughout

the project, NIST performed various other critical roles. As part

of the initial assessment, NIST surveyed 12,000 binary and

ternary metallic phase diagrams to identify eutectic compositions

and congruently melting compounds with potential as

candidate solder alloys. NIST had a leadership role in formulating

the down selection criteria, and conducted the metallurgical

analysis and metallography for the project. NIST also coordinated

the

|

|

.jpg)

.jpg)

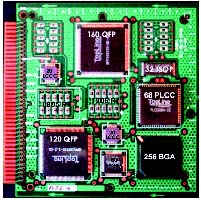

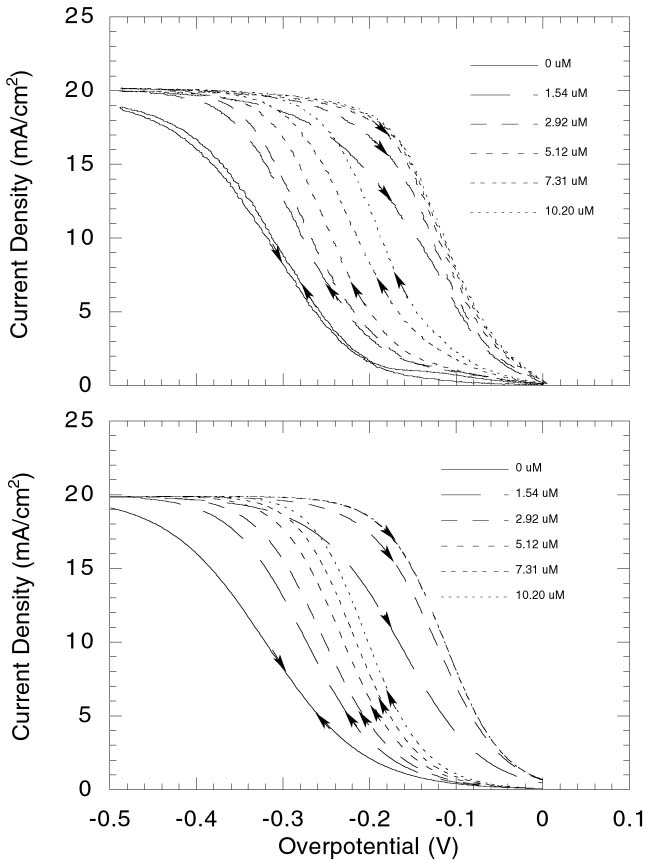

Figure 1. Plastic leaded chip carriers on ceramic (top)

and polymeric (bottom) substrates assembled with

Pb-free solders and surface finishes.

final analysis of the data, the determination of conclusions

and recommendations, and the writing of the NCMS final report.

The High Temperature Fatigue Resistant Solder Project

was summarized in an invited article in Advanced Materials

and Processes, April 2001, written by NIST staff. In addition,

a technical paper presented by NIST was selected as one of the

5 best papers out of 58 presented at the TMS 2001

Annual Meeting Symposium on "Recent Progress in Pb-Free

Solders and Soldering Technologies." This distinction included

electronic

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

publication on the web through e-JOM as well as publication

in the June issue of JOM journal (Journal of Metals).

Major conclusions of the High Temperature Fatigue Solder Project are:

• Six lead-free alloy compositions were identified that exhibit

fatigue performance during -55 °C to +160 °C cycling

of a wide range of components which is superior to

the industry standard eutectic Sn-Ag alloy.

• The seven lead-free alloys cycled with ball grid array

(BGA) packages through 0 °C to +100 °C and -40 °C to +125

°C cycling all outperformed Sn-Pb eutectic solder.

• Manufacturing of these alloys and generation of solder

pastes does not present any special problems.

• Present manufacturing equipment can be used to

build assemblies in many cases.

• Alloy costs will not be a major factor.

|

|

|

|

|

|

|

|

|

|

|

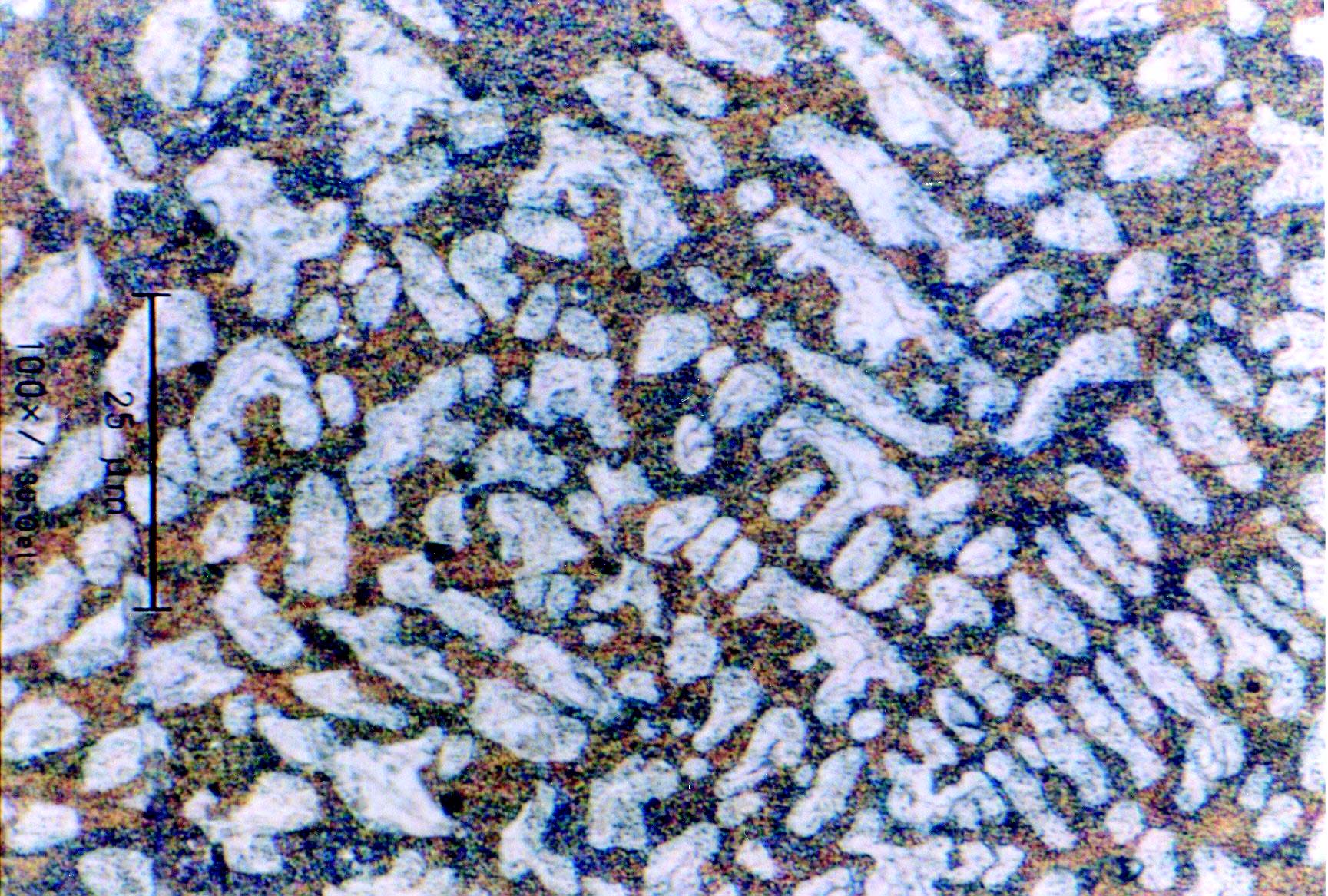

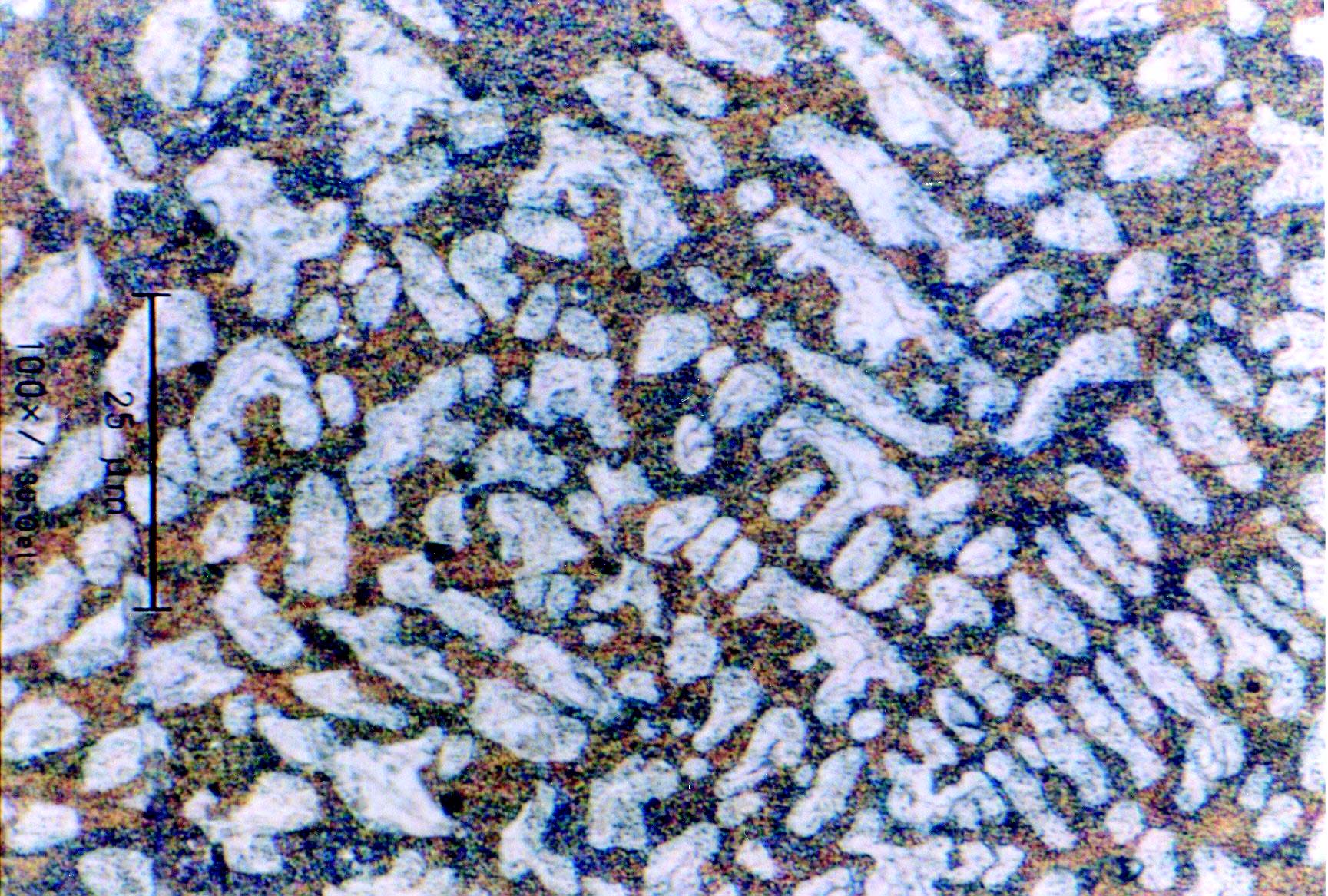

Figure 3 Microstructure of an experimental alloy.

|

|

|

|

|

|

"NIST personnel brought unique skills and expertise to

both NCMS projects [the Lead-Free Solder Project, and the

High Temperature Fatigue Resistant Solders Project]. Without

the support from NIST, both these projects would have

extended over a longer period of time and would have been more costly

to the project's industrial partners."

— Duane Napp, NCMS Program Manager

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

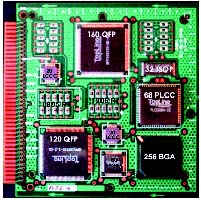

Figure 2. Reliability Test Vehicle used to

test manufacturability and thermal fatigue resistance of

a variety of surface mount components on printed

circuit boards.

|

|

|

|

|

|

|

|

|

|

For More Information

On This Topic:

|

|

NCMS High Temperature Fatigue Resistant Solder Project Final Report, NCMS,

Ann Arbor, MI, 2001. Frank W. Gayle, "Fatigue-Resistant, High Temperature Solder,"

Advanced Materials & Processes 159 (4), April 2001, p. 43-44; Frank W. Gayle, et al.,

"High Temperature Lead-free Solder for Microelectronics," JOM, June 2001, p. 17-21.

|

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

Process Modeling of Low Cost Powder

Metallurgy Technology for Particle Reinforced Aluminum

|

|

|

|

|

Major research efforts within the U.S. auto industry are driven by the need to reduce the weight of future vehicles to meet U.S.

Council for Automotive Research (USCAR) and Partnership for a New Generation of Vehicles (PNGV) goals. This can most readily

be accomplished by the substitution of lightweight materials for the heavy materials currently used. With the completion of this

project, NIST has assisted industry in developing a low cost powder processing technology for aluminum alloy and

particle-reinforced aluminum parts that may be substituted for iron-based powder metallurgy products. Efforts to mass produce acceptable parts

using press-and-sinter and direct powder forging are underway. The NIST part of this effort focused on modeling each step in these

consolidation processes from powder to fully dense part. Modeling provided a basis for rapidly designing successful processes.

|

|

|

|

|

Reducing the mass of certain engine components, such

as connecting rods and transmission fluid gerotor pumps, can

have a large effect on engine efficiency and responsiveness far

beyond the simple weight reduction. For this reason, these

components were targeted by the U.S. Automotive Materials

Partnership (USAMP) as candidates for their program on Low Cost

Powder Metallurgy Technology for Particle Reinforced

Aluminum. Currently, these components are produced from steel powder.

NIST provided models of many of the various processes

that had to be modified to switch to aluminum and these

contributions are summarized here. Dr. John Allison of Ford and

former Chairman of the USAMP Advanced Metals Division wrote

of the NIST contributions, "The modeling effort … is an

integral and very critical aspect of this program," and "[NIST's]

impact could eventually extend well beyond this particular project."

In collaboration with the Micromechanics Centre at

Cambridge University, a physically based constitutive law for

consolidation of reinforced powder was developed. Its validity was tested

at NIST on powders relevant to the USAMP program and found

to accurately describe the consolidation behavior of

reinforced powders. This model was implemented in a finite element

model to predict the behavior of parts having complex shapes.

USAMP funded a small business to develop the model for

the specific shapes of interest to the program. The

computer-modeling package is now available in a user-friendly,

commercially supported form.

.jpg)

.jpg)

Figure 1. Parts targeted by the USAMP project on Low

Cost PM Technology for Particle Reinforced Aluminum.

As part of the validation process, NIST developed databases

for the materials of interest. These databases included the

consolidation behavior of the various ductile phases as a function

of temperature and the effect of various concentrations

of reinforcement on this behavior. Additional modeling was

carried out at NIST to provide guidance to the efforts. For example,

one direction undertaken was to develop materials based on

blends of soft, unalloyed aluminum powder with hard,

alloyed powders. A natural question arose as to what minimum

amount of unalloyed aluminum was needed to achieve a given level

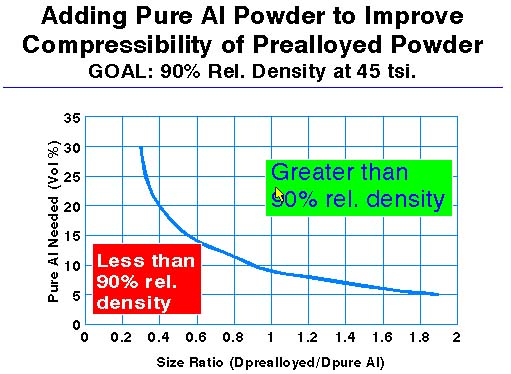

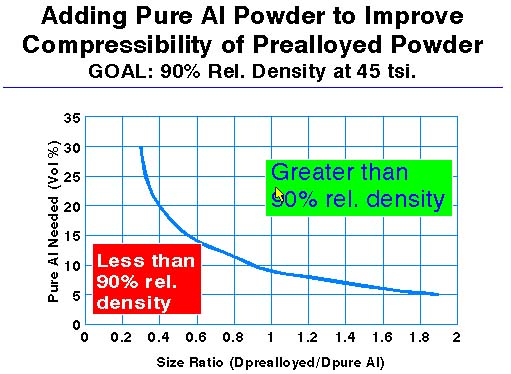

of density during cold pressing. The modeling approach

was modified to provide some guidance and the nomograph

in Figure 3 was the result. This particular figure predicts the

|

|

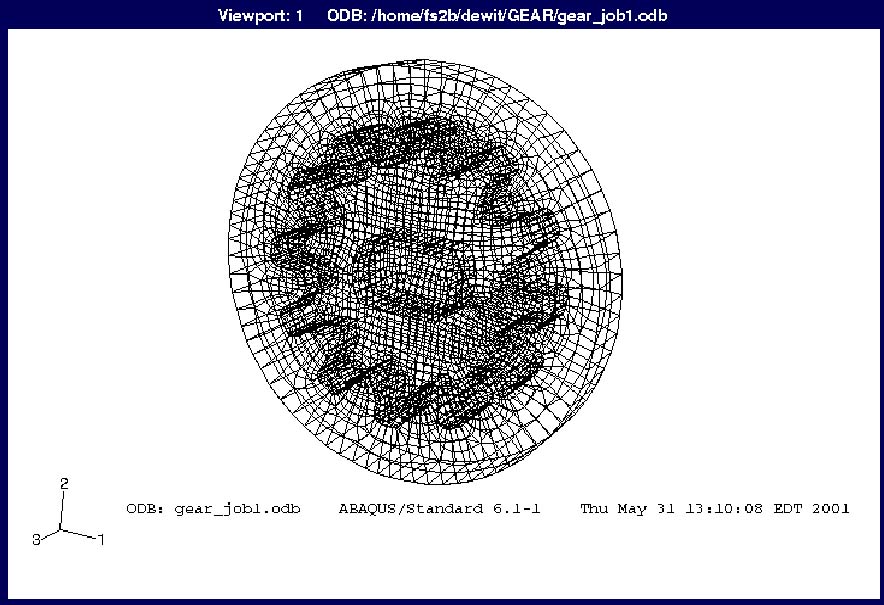

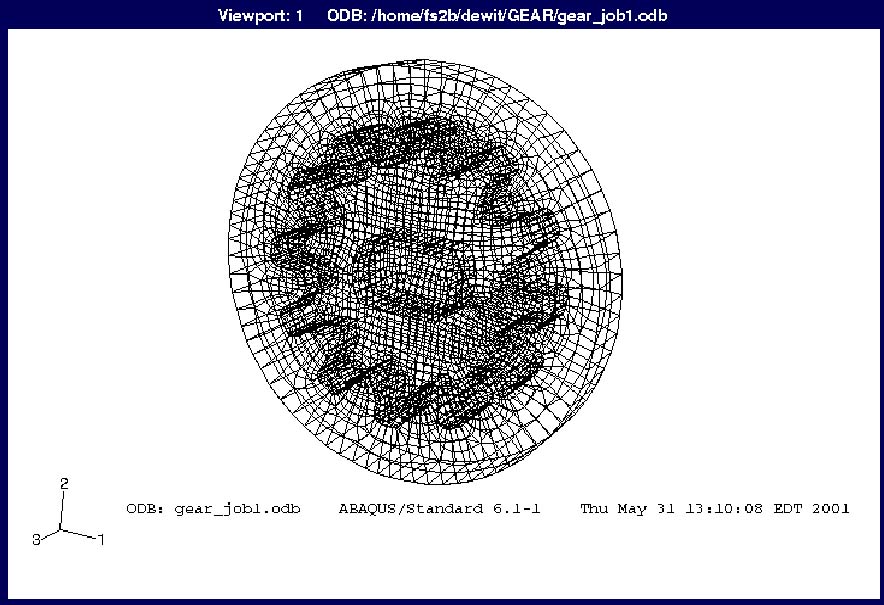

Figure 2. Finite Element Model of Gerotor Die filled

with powder that is modeled using the constitutive equation

and data developed in this project.

amount of aluminum needed to reach a relative density of 0.90

as a function of the size of the soft aluminum powder

particles relative to the hard powder particles under a pressure of

620 MPa (45 tsi). The figure can be easily changed to

address particular industrial requirements. It emphasizes the

importance of particle size on the resulting behavior.

Another area in which process modeling helped was in sintering.

In contrast to some other systems, sintering in

powder metallurgy is carried out mainly to develop strength. No

change in density is normally desired since this results in distortion

or cracking.The modeling approach adopted for this

project attempted to simply predict the time and temperature required

Figure 3. Effective of pure aluminum on compressability

of prealloyed powder.

to homogenize the elemental blends into the intended

alloy. Again, a strong dependence on particle size was found.

This provided guidance to the powder suppliers as to what

sieve sizes were desireable to blend to achieve homogenization on

an industrial timeframe. NIST provided assistance to this

project when an unexpected issue _ powder flowability _ stood in

the

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

way of industrial implementation. Mechanical properties

studies showed that these materials would only be successful if

a relatively fine SiC powder were used as the reinforcement.

NIST research showed that fine aluminum powders were required to

be blended with such fine SiC powders. However, the

resulting mixture would not flow down commercial feed tubes or

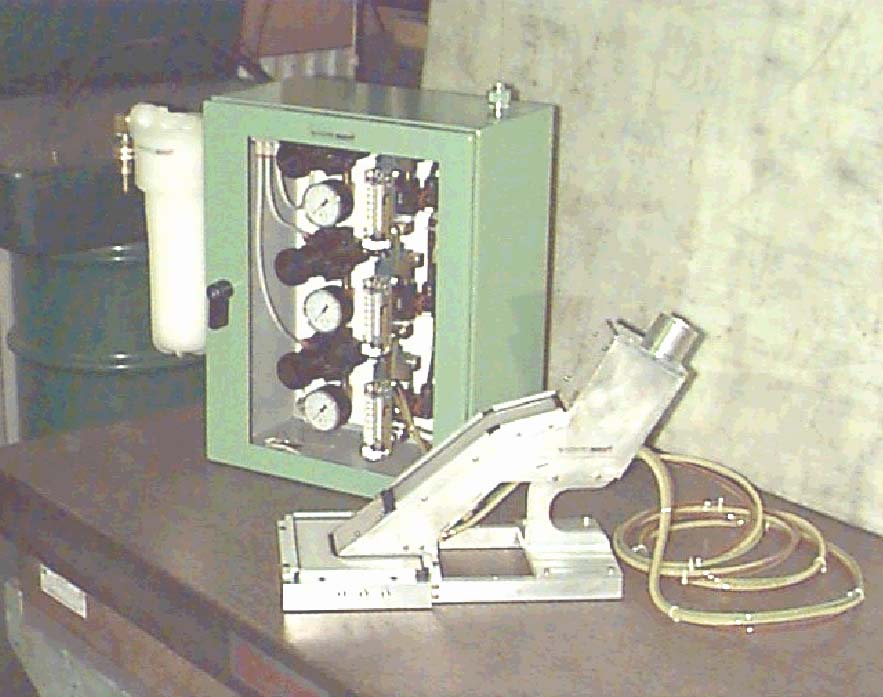

through feed shoes into the dies for pressing. Using the Small

Business Innovative Research (SBIR) program at NIST, modeling

of powder flowability was carried out in conjunction with a

small business. One outcome of this work was a means of using a

gas to lubricate the powder particles and make flow

possible.This technology was incorporated into the fluidized feedshoe

shown in Figure 4. It has been used to make many sorts of

powders flow from cosmetic and medicinal powders to ultrafine

carbide

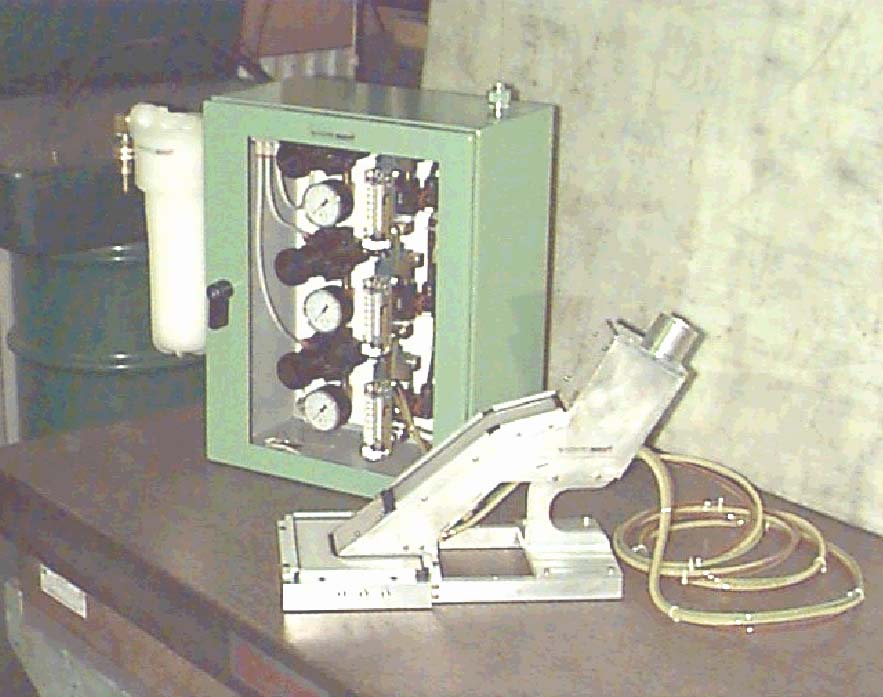

Figure 4. Fluidized feedshoe and associated equipment

for improving the flowability of fine or irregularly

shaped powders into die cavities.

powders for tools. The fluidized feedshoe is now

commercially available from a powder press manufacturer as an accessory

to their presses. It is being used by a number of U.S. companies

to make parts using fine powders or better parts using

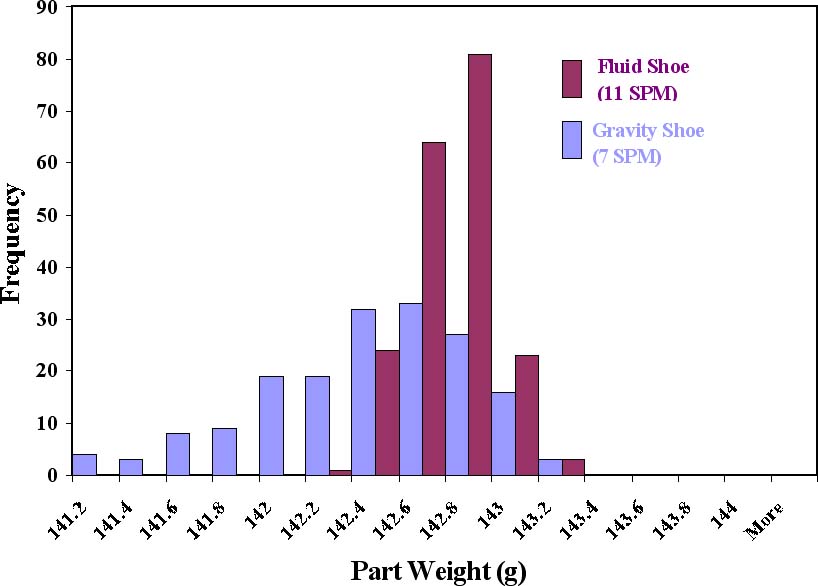

existing powders. One unexpected outcome of the technology is

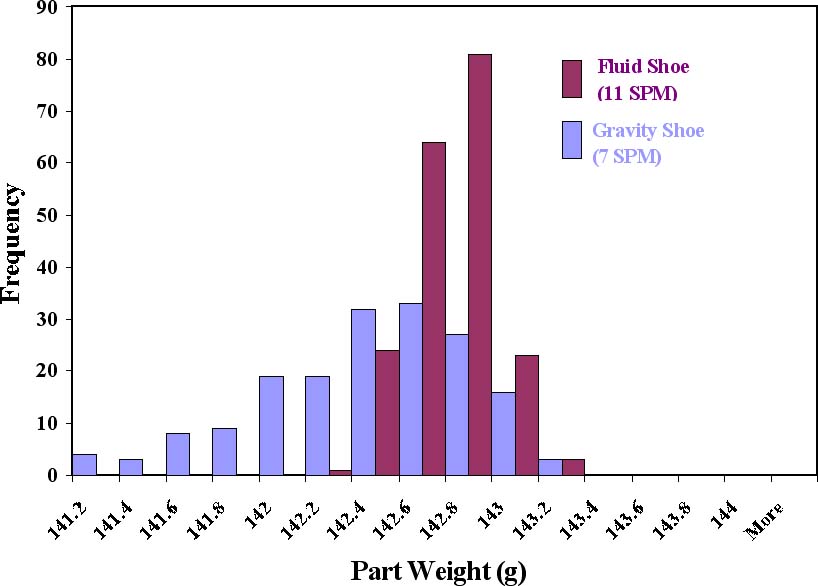

shown in Figure 5 _ improved part uniformity. This figure shows

the improved mass uniformity using the fluidized feedshoe.

This mass uniformity translates into improved dimensional

tolerances for PM parts. It also permits more rapid feeding and

increases productivity.

|

|

Figure 5. Weight distribution for gears made with

and without the fluidized feedshoe technology.

|

|

|

|

|

For More Information

On This Topic:

|

|

R. J. Fields, T. Zahrah, and Y. Shim

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

Standard Problems for Computational Micromagnetics |

|

|

Computational micromagnetic modeling is the dominant method used to calculate magnetization patterns and dynamics in

materials and devices on length scales from nanometers to several micrometers. The demand for accurate micromagnetic modeling is

accelerating as the industry wide trend of over 60% per year increase in bit density for hard disks creates increasing demands on our ability

to predict and control the magnetization in materials and devices. Development of new magnetic devices including magnetic

random access memory (MRAM) increasingly depends on the behavior of magnetization on nanometer length scales. Our activity in

computational micromagnetics, started in 1995, is designed to facilitate testing of micromagnetic computer codes by specifying and publicizing

a number of standard problems and then computing, collecting, comparing and publishing solutions to these problems.

|

|

|

|

|

Micromagnetic modeling is used to compute magnetic

domain structure and dynamics in magnetic materials starting

from sample morphology, materials properties, and applied fields.

This type of modeling is a very important part of device

design, particularly for read heads in hard drives and magnetic

random access memory (MRAM) cells. Micromagnetic modeling

has also contributed a large amount to our understanding of

recording processes and noise in magnetic recording media.

Our involvement in standard problems was designed to fill

a need in industrial and academic labs for a method to check

the accuracy of micromagnetic modeling software, usually

developed independently in each lab, and tested by parts, energy term

by energy term. Beyond finding "bugs" in software, the

standard problems also provide benchmarks for modeling practice

which can help to avoid errors introduced by overly

coarse discretization, or loose convergence criteria.

The standard problems were one of two action items

recommended in the initial workshop of the micromagnetic

modeling activity group (mMAG) that drew approximately 100 attendees.

This workshop was held as an evening session at the

1995 INTERMAG conference, and was sponsored by MSEL's

Center for Theoretical and Computational Materials Science.

The standard problems were designed with the following

criteria in mind:

• Geometries and materials properties should be similar to

"real-world" applications.

• Specifications should be loose enough to allow

different computational methods to be used, but tight enough

to ensure that results can be meaningfully compared.

• The scope of the problem should be small enough that it

would not be too expensive in manpower or computational

time to compute a solution.

• The problems should be significant enough to allow

solutions to be published in the usual scientific journals.

The specifications for the standard problems presented

below were all written by NIST, based on suggestions received

from members of the micromagnetic modeling community.

Solutions to these problems were calculated by NIST and by

contributors from across the globe. Detailed specifications and results

are available on the mMAG website:

http://www.ctcms.nist.gov/~rdm/mumag.html

Standard Problem #1 is a 1 mm x 2 mm x 20 nm rectangle

of material with properties to mimic Permalloy, and the

requested results are hysteresis loops and magnetization patterns

obtained at zero applied field. When the first few submitted results

were

|

|

found to have wide disagreement, we quickly decided to

protect the contributors by collecting results anonymously.

Nine solutions were collected and posted on the mMAG website

with widely varying results. While Standard Problem #1 may

be regarded as a failure regarding its use in checking

micromagnetic software, it remains important as the first attempt at a

public standard problem in micromagnetics, and as a

computational challenge.

Standard Problems #2 and #3 were developed from

discussions at a second mMAG workshop held as an evening session of

the 1998 Joint MMM-INTERMAG conference.

Standard Problem #2 is a variable-sized bar of material

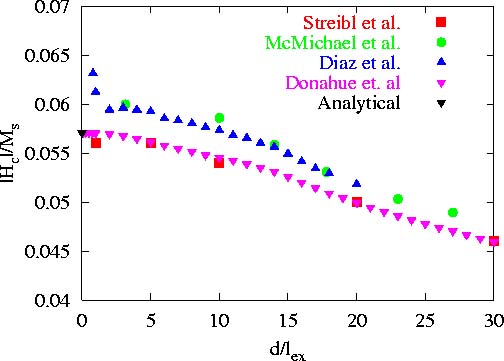

with aspect ratios of 5:1:0.1. All lengths are expressed in units of

the magnetostatic exchange length, which is a function of the

material exchange stiffness constant and the magnetization. The

results collected for comparison are the coercive field and the

remanant magnetization as a function of the width of the rectangle.

Four solutions for Problem #2 have been collected and posted

on the mMAG website. Three of these results were first

presented at the MMM'99 conference in a special evening session

on micromagnetic standard problems. The attendees,

numbering more than 100, were delighted to see good agreement

between results calculated independently and by different methods.

The fourth Problem #2 result is our revision of our earlier result

and an analytical result for the coercivity in the limit of a

small particle.

A comparison of coercivity values calculated for

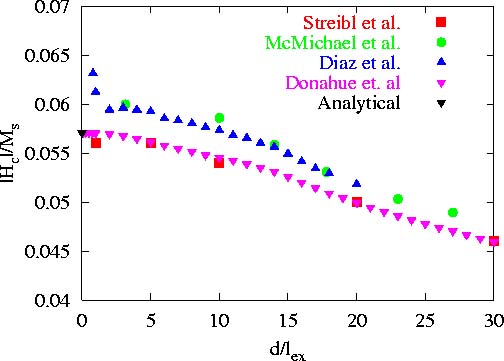

Standard Problem #2.

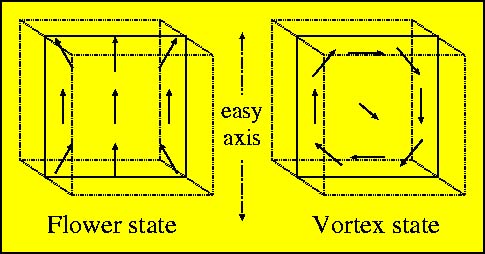

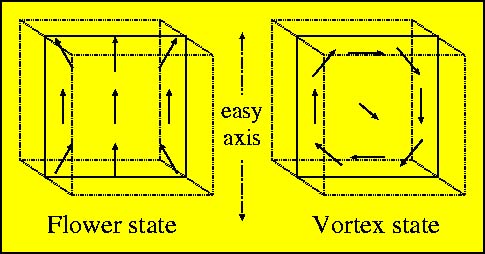

Standard Problem #3 is specifically designed for 3-D

calculations. The object is to calculate the minimum energy

magnetization configuration for a cube of material with some

uniaxial anisotropy. For small cubes, the minimum energy

configuration is a "flower" state, and for larger cubes, the expected

minimum energy state is a "vortex" state. The result collected

for comparison is the critical length of the cube edge for which

the energies of the two states are equal. One of the

submitted results revealed a surprise "twisted flower state" which

has lower energy than either the flower state or the vortex state.

|

|

|

|

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

Diagrams of the flower state and vortex state from

the specification for Standard Problem #3.

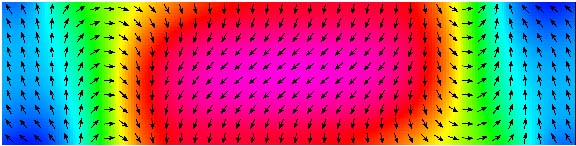

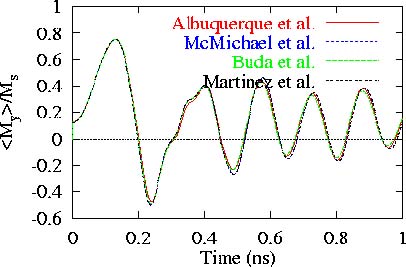

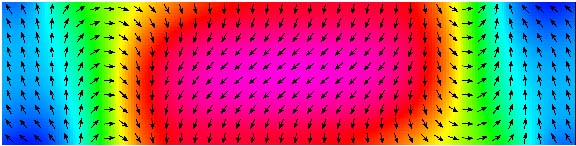

Standard Problem #4 is designed to test dynamic

calculations based on Landau-Lifshitz-Gilbert equations of motion.

The details of magnetization dynamics are becoming more

important for magnetic recording as data rates increase, and for

MRAM development, the details of switching behavior are critical.

In Problem #4, switching is calculated for a 500 nm x 125 nm

x 3 nm rectangle of Permalloy starting from an equilibrium state

in zero applied field. One of two specified applied fields

are turned on to induce switching, and the magnetization

dynamics are traced as a function of time. For one applied field,

the magnetization rotates in the same direction everywhere in

the sample, but for the other, the switching is more

complicated, with rotation starting in one direction near the ends of the

bar and in the other direction in the middle.

(a)

(b)

Snapshot of the magnetization during reversal (a) and

(b) magnetization dynamics from Standard Problem #4.

|

|

These micromagnetic standard problems provide

computational physicists and engineers in industry and academia

with benchmarks for micromagnetic software development

and micromagnetic modeling practice. By assuming a leadership

role in the field, by providing standard problem specifications and

by providing electronic access to submitted solutions including

our own solutions, we have raised the quality of

micromagnetic modeling, and we have provided a means to assess the

reliability of micromagnetic modeling results for modelers and for

their customers. NIST could not have made these standard

problems without the contributions of colleagues across the

globe, especially in Europe, who computed and provided solutions

to the standard problems.

|

|

|

|

|

For More Information

On This Topic:

|

|

Standard Problem specifications and results are published on the

mMAG web page: http://www.ctcms.nist.gov/~rdm/mumag.html

R. McMichael, (NIST/MSEL) and M. Donahue and D. Porter (NIST/ITL)

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

Particle Temperature Measurement Issues for Thermal Spray Processing

|

|

|

|

|

Temperature and velocity measurements of particles and droplets provide important process parameter data for modeling and

control of the Thermal Spray (TS) coating process. Accurate measurement of particle temperature using non-contact temperature

sensors depends on the use of appropriate sensor calibration procedures. In this project completed this year, we demonstrated

several methods for calibrating two-color optical pyrometers including a high temperature blackbody and a tungsten ribbon standard lamp

as calibration sources. Comparing the different methods shows that the absolute temperature and wavelength-dependent emissivity of

any non-blackbody calibration source must be well known to obtain an accurate sensor calibration. Further, emissivity data on

individual heated particles were shown to improve the accuracy of particle temperature measurement by two-color pyrometry.

|

|

|

|

|

In the air plasma thermal spray (TS) process for

producing coatings, solid particles are injected into and heated by a

plasma jet. From the beginning of the injection process

through interactions with the plasma jet, the particles will have

wide ranges of temperatures, velocities and trajectories that

then translate into a microstructure as the impinging particles

solidify to form the coating layer. Particle diagnostics within the

TS plume are favored as a means of improving process

reproducibility because they yield information on both the physics of

the coating process itself and the process variability. TS

particle sensors fill two roles. They are used in quality control

operations to "tune" thermal spray torches to ensure

consistent coating deposition. They are also widely used in thermal

spray research, including developing parameter sets for new

spray materials, evaluating improved spray torches, and

studying relationships between processing conditions and

coating properties. Such diagnostics make rational process

improvement possible, a difficult endeavor when only process settings,

such as torch power or gas pressures, or a final coating property

can be measured.

These important particle data are provided by

non-contact optical temperature and velocity measurements from sensors

and software that process light intensity readings from

particles within the TS plume. Two-wavelength ratio pyrometry

is usually employed for measuring particle temperatures because

it is insensitive to particle size, absolute emissivity and

particle position within the sensor field of view. It requires only that

the particle emissivity not vary over the operating wavelengths

of the sensor, known as the graybody assumption.

Several approaches are now available: 1) Single particle,

non-imaging sensors that collect data one particle at a time and average

the results from several particles at the same location or, by

moving the sensor position, within a defined area; 2) Particle

ensemble, non-imaging techniques that acquire data related to some

average temperature and velocity of the particle stream; and 3)

Imaging pyrometry that measures multiple individual particles

simultaneously by focused imaging of a large volume of the

spray plume. Temperature measurement using these optical

techniques requires a calibration procedure to provide the

appropriate coefficients for conversion of the measured light intensities

to temperature values.

In the last few years NIST has been working to assess

industry needs and address several of these non-contact

temperature measurement issues. Industry needs have been determined

by reviewing published papers and reports, discussions

with colleagues, and through workshops (several sponsored by

NIST) focused on issues related to the TS coating industry. At

the Workshop on Non-Contact Thermometry held at NIST

in October, 2000, the importance of absolute

temperature measurement and traceability for industrial applications

was

|

|

discussed. At the recent workshop on Thermal Spray

Process Reliability held at NIST in January, 2001, the consensus

was that the reproducibility and reliability of TS coatings need to

be improved in order to realize the full benefits of this technology.

As a possible solution, representatives of industry and

academe expressed interest in combining process measurements

with coating property data into an integrated database that

would provide guidance in the use of thermal spray technology

to coating developers and potential users alike. Their hope is

that improved process measurements, coupled with

increased awareness of thermal spray as a well-understood means

for enhancing surface properties and synthesizing novel

materials will expand its broad-based benefit. A report is available

that includes the workshop presentations and discussions

(NISTIR 6776.)

During the Thermal Spray Process Reliability

workshop, specific questions were raised concerning the calibration

of particle temperature sensors, and how the properties of

the particles being measured (e.g., composition, oxidation,

etc.) affect the accuracy with which temperature is determined.

In response, the Metallurgy Division has taken steps to

outline recommended calibration procedures for thermal spray

particle temperature sensors and to provide particle emissivity data

for improving temperature measurement accuracy.

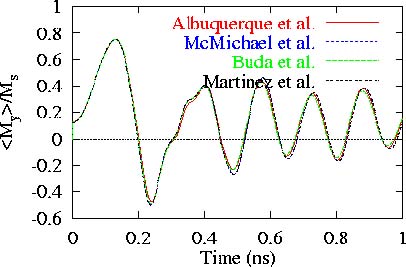

Current work on calibration procedures has involved

evaluating the use of tungsten standard ribbon lamps as calibration

sources for two-color pyrometers. Tungsten lamps are used

because they are readily available, but because of their deviation

from graybody behavior they are not as suitable as an ideal

blackbody calibration source. Errors caused by the deviation from

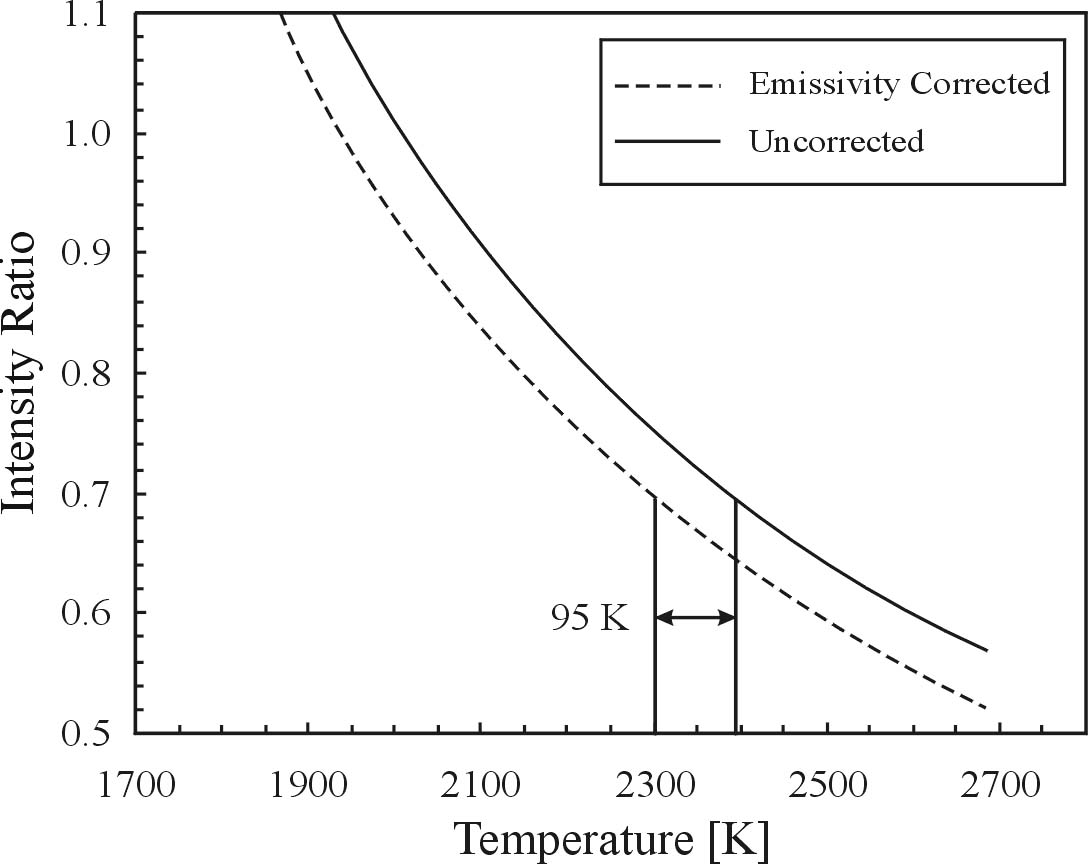

graybody behavior are shown in Figure 1. They can be corrected

using tungsten emissivity data available in the literature, or by

direct measurement of the emissivity of the lamp by spectroscopy.

An additional calibration issue involves the fact that

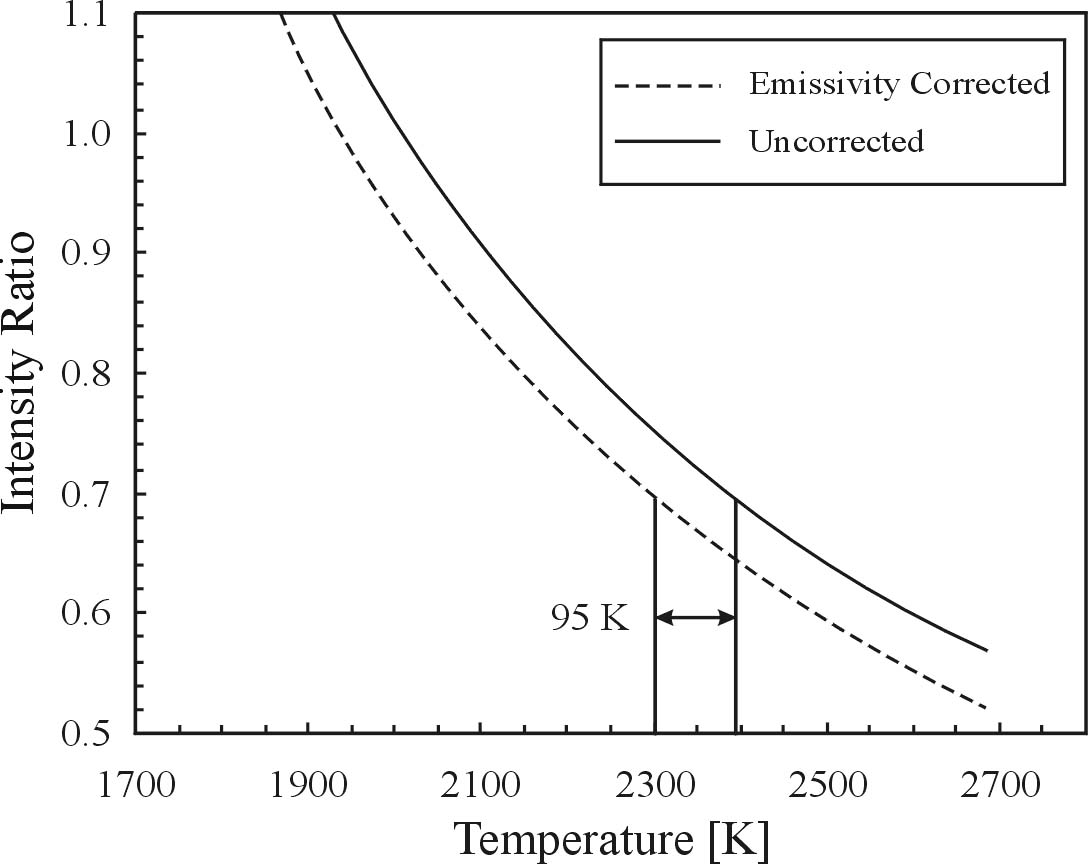

tungsten lamps are typically calibrated to serve as radiance

temperature standards. These lamps are appropriate for calibrating

single-color but not two-color pyrometers. The reason is that

the radiance temperature scale, which is defined for a

perfectly radiating surface (e.g., blackbody, e = 1), is meaningful only

at the calibrated wavelength of the lamp, and therefore

it cannot be transferred to a pyrometer that operates at two

wavelengths. Absolute temperature of the filament must be determined

and used instead. Radiance temperature can be converted to

absolute temperature using the normal spectral emissivity of tungsten

at the lamp wavelength. Though easily addressed, this error is

often overlooked, resulting in serious systematic errors in

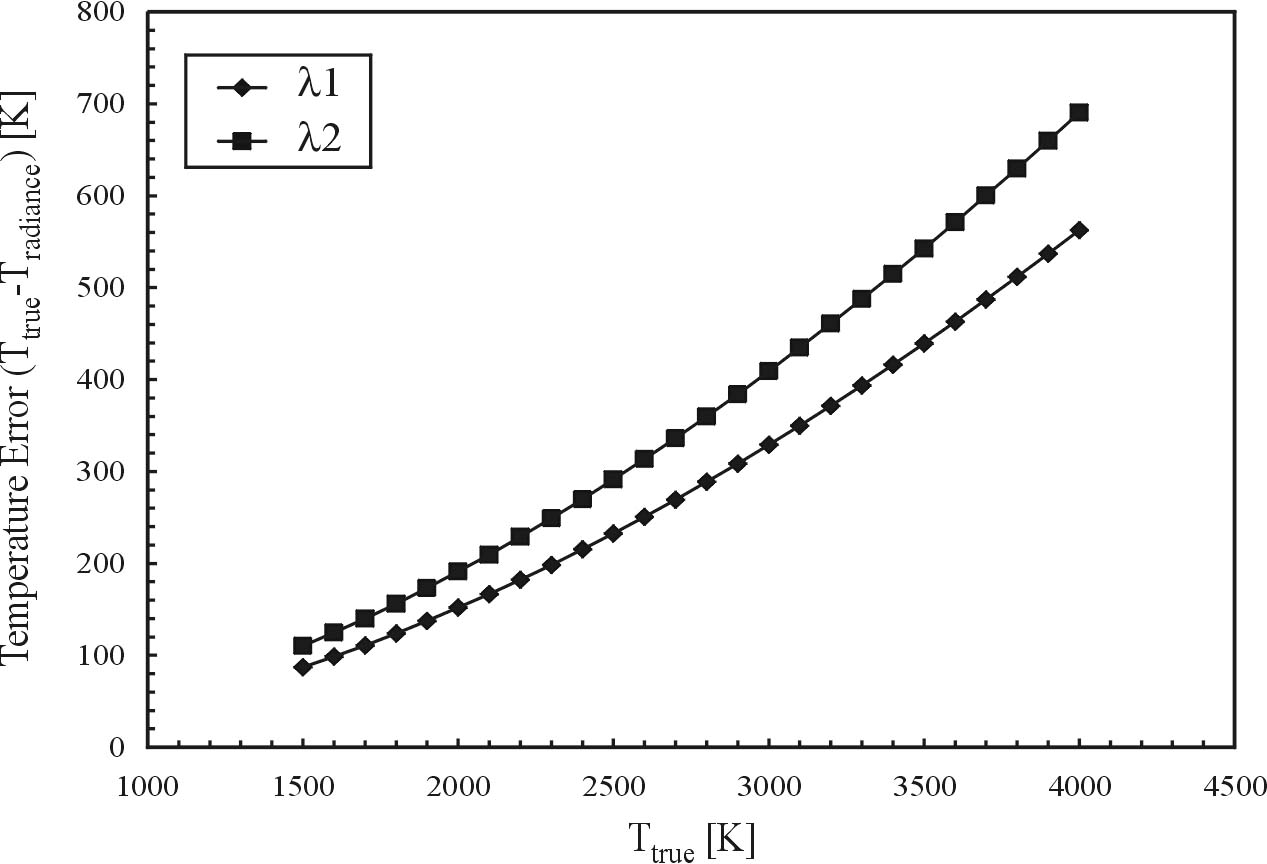

particle temperature measurements. Figure 2 shows the errors

incurred using radiance temperature rather than absolute temperature

in the calibration of a generic two-color pyrometer. The accuracy

of

|

|

|

|

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

these corrections using literature data is evaluated by

comparing the resulting calibration to calibrations obtained using a

blackbody.

With the transfer of these results throught the

technical literature, our project on Thermal Spray Processing has

now been successfully completed.

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 1. This figure shows the effect of the deviation

from graybody behavior of the calibration source for a

two-color imaging pyrometer.

|

|

Figure 2. This graph shows the error associated with

the use of radiance temperature rather than true

temperature in the calibration of a generic two-wavelength

pyrometer operating at l1 = 700 nm and l2 = 900 nm. The

calibration source has a normal spectral emissivity

of e = 0.43.

|

|

|

|

|

|

For More Information

On This Topic:

|

|

S. D. Ridder, Thermal Spray Process Reliability: Sensors and

Diagnostics, NISTIR 6776, August, 2001. S. D. Ridder, F. S. Biancaniello, S. P. Mates, and R. D. Jiggetts

(NIST/MSEL)

|

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

NIST Research for Springback Predictability and Sheet Metal Forming in the Auto Industry

|

|

|

|

|

Market and regulatory pressures are driving the automotive industry to develop and use new materials and manufacturing

methods while competitive pressures are forcing them to keep costs low and reduce the time required to bring a new vehicle from concept

to market. Current automotive production technology has evolved around stamping of relatively low strength steel to form

automotive body panels and components. While this approach was acceptable when designs and materials were not changing dramatically,

this process of die design and tryout may limit U.S. automakers' abilities to utilize new materials in their designs or to bring a new

design rapidly to market. NIST has been working with the automotive industry to improve the die design process and reduce die

development and tryout costs.

|

|

|

|

|

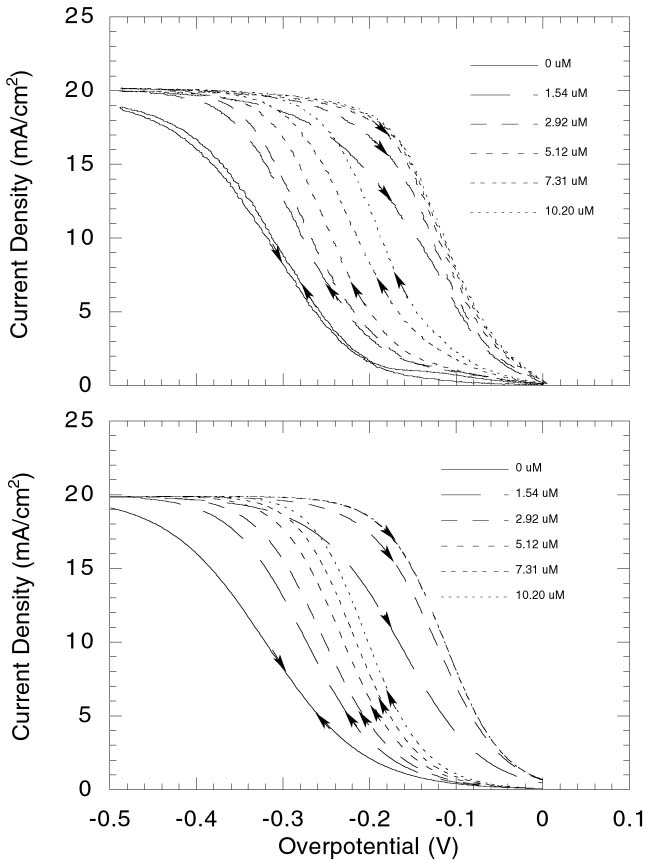

One area that has long been a concern to the auto industry,

but has become a major concern due to the increasing pressure to

use lighter materials and reduce die development time and costs,

is springback. When the material being formed is a low

strength material, springback from the die face following stamping will

be relatively small and can be accounted for by experience

and during die tryout. This sitation is no longer the case - new,

higher strength steels and aluminum alloys have greater

springback magnitudes; designs of increased complexity are often

accompanied by unpredictable springback magnitudes and directions;

and demands continue for reduce time to market. These

factors point to the need for spingback to be addressed earlier in the

die design, development and tryout process.

The industry thus needs better predictive models based on

a sound fundamental understanding of springback phenomena

and appropriate measurements, standards, and data. In response

to this need, a consortium of aluminum and steel producers,

a software company, and the three automotive manufacturers

and their suppliers received support from NIST for 5 years

to develop finite element software that can predict springback.

The resulting ATP Springback Predictability Project (SPP)

greatly reduced the uncertainty in springback predictions by

finite element models and brought a higher level of understanding

of springback to the sheet metal forming industry. The

ATP/SPP concluded in October 2000.

Figure 1. Plaque given to NIST staff that

presented research results to SPP during the ATP funded phase.

|

|

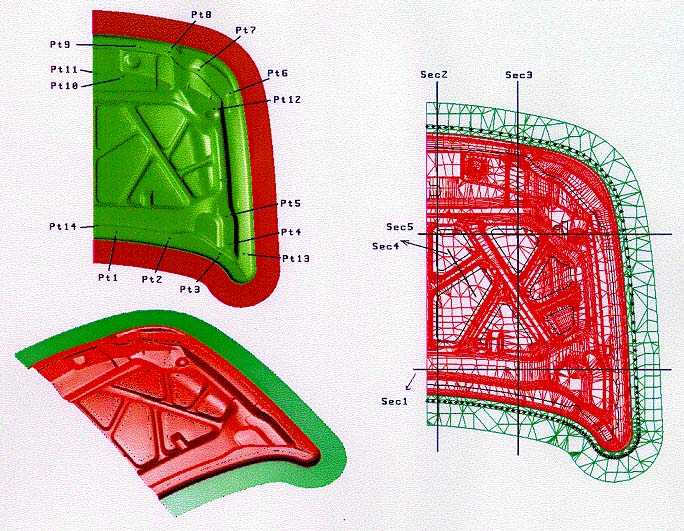

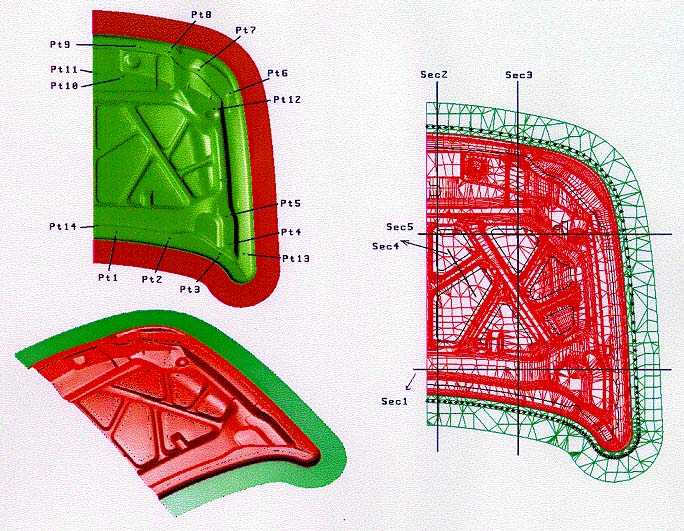

Figure 2. The inner panel of a car hood was one of

the components targeted by industry for in-depth

investigation of its springback behavior.

The Metallurgy Division was involved with this project from

its beginning, carrying on a set of parallel, non-proprietary

research projects complementing SPP activities. There were

three projects: fundamental dislocation studies,

deformation-induced surface roughening, and standard test methods. The

most significant contributions by these projects to a deeper

understanding of springback and forming in general were:

• A model based on percolation theory was derived to

describe and predict the movement of dislocations through a

work-hardened microstructure.

• Analyses and experimental measurements demonstrated

the importance of anelastic effects in plastic deformation

and springback.

• A new experimental technique, ultra small angle x-ray

scattering (USAXS) imaging, was shown to hold promise as a

useful tool for studying dislocation structures

in situ. When a USAXS scan is made, the data are in the form of a

slit-smeared scan through a single-direction in

reciprocal space. Once a scan is made, interesting features can

be identified and the analyzer crystals can be set to a

specific location on the scattering curve. The sample can then

be imaged through the analyzer stage. What makes

this technique potentially useful is that USAXS imaging

can select weak scattering components (such as

dislocations) and form the image from just these components.

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

• The influence of microstructural and compositional

differences on the roughening rate during uniaxial straining

was determined. A generic model for

deformation-induced surface roughening was developed.

• A biaxial test facility was set up at NIST to generate

well defined multiaxial strain states to simulate

forming conditions and develop standard measurement methods.

• A well attended conference on the fundamentals of

dislocations and plasticity was held at NIST to provide U.S.

industry with the most up-to-date science.

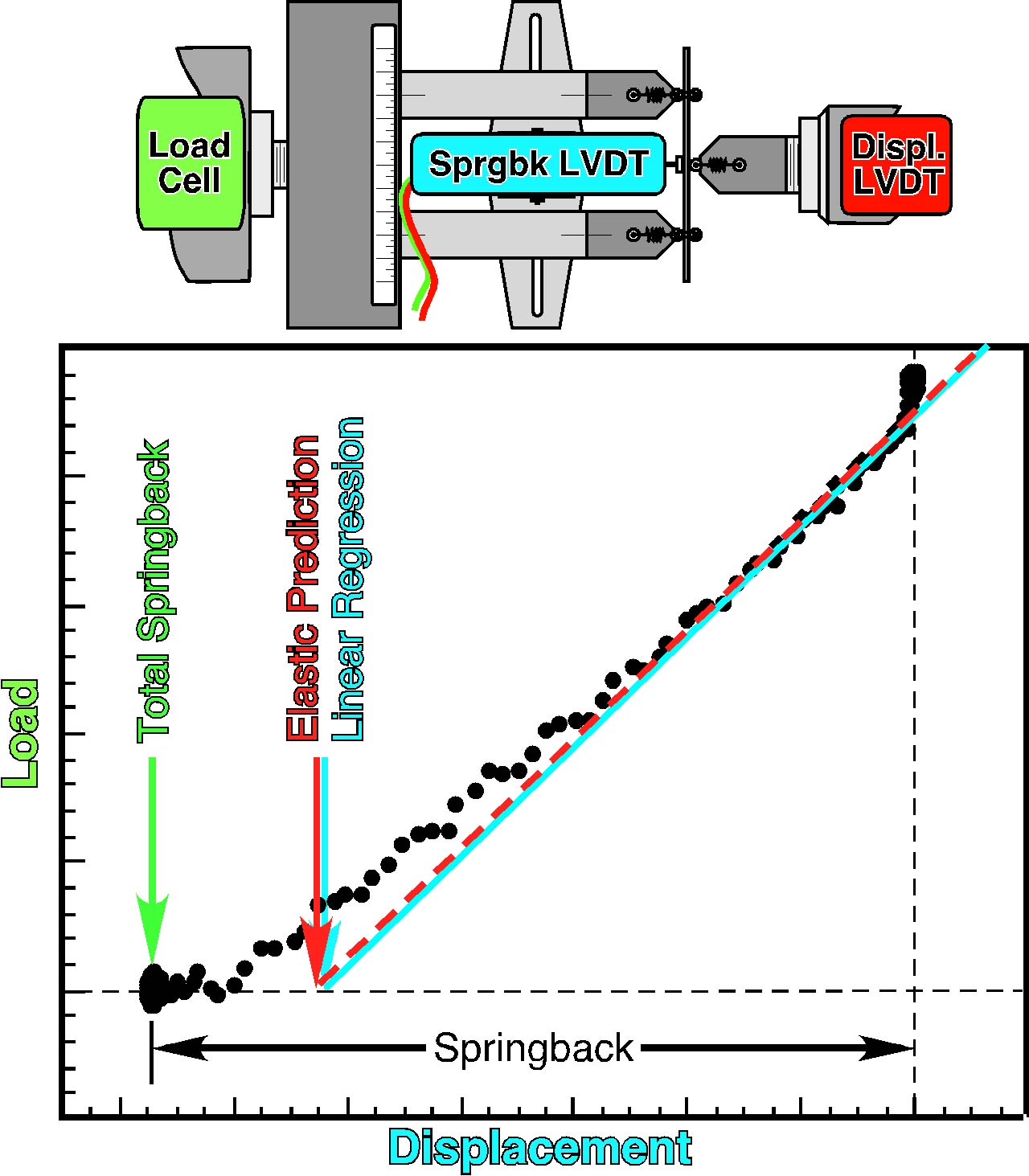

Figure 3. Springback measured in 3-point bend

showing linear and non-lined components.

The Springback Predictability Project and joint

venture partnership was considered so successful that industry

decided to continue its activities with their own funds after ATP

support ended. A poll was taken of the industrial members to decide

the assignment of priorities to a list of 17 activities.

Continued interaction with the NIST forming research effort was

ranked second highest in priority.

NIST has responded to this request from industry. The

three projects that arose from the initial industrial interaction form

the

|

|

basis of the Forming of Lightweight Materials Program

described in this Annual Report of the Metallurgy Division. Some

specific actions to address the industrial needs are:

• The conclusion that anelastic recovery may be able to

account for this remaining uncertainty was well received by

the SPP members. To enable obtaining a better

understanding of the role of anelastic deformation in springback

and dislocation dynamics in surface roughening, a

dynamic mechanical analyzer was purchased. This system

is capable of testing mechanical testing at frequencies up

to 200 Hz and temperatures from (_150 to 600) °C with

a strain resolution of 1.0 nm. This system can be used

for dislocation damping (internal friction)

measurements, creep, stress relaxation measurements, and anelastic

strain recovery measurements. This system will enable NIST

to relate fundamental dislocation structures and dynamics

to the deformation behavior important to the

forming industry.

• We will participate in two other industry-led consortia:

Warm Forming of Aluminum and Active, Flexible

Binder Program for Metal Stampings. Our involvement will be

to investigate the elevated temperature formability of

sheet metal by upgrading our biaxial tester to carry out tests

on heated metal. The role of roughening on friction will

also be pursued to improve predictability.

Figure 4. Inner panel of car hood.

|

|

|

|

|

|

|

|

|

For More Information

On This Topic:

|

|

R. J. Fields, T. Foecke, L. E. Levine, and R. E. Ricker (NIST/MSEL)

|

|

|

|

|

|

|

|

| Back to the top |

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

Thermodynamic and Kinetic Modeling of Multicomponent Alloys

|

|

|

|

|

|

Commercial alloys rarely consist of only two elements and some contain up to 10 elements. In addition, many important

industrial processes rely on diffusion to control the formation and dissolution of precipitate phases within a matrix or at an interface.

The development of thermodynamic and diffusion databases enables the extrapolation of these properties from binary and ternary

systems to needed higher order systems. NIST's development of such databases for Ni-base superalloys allows the modeling of

various processing applications. The approach has been shown to give reasonable predictions for complex alloys and provides a

compact storage method for vast quantities of data.

|

|

|

|

|

|

During the last decade, researchers from the Metallurgy

Division have collaborated with scientists from universities and

industry on several projects with emphasis on modeling tools for

the design and manufacture of superalloys. Structural parts

made from superalloys not only must withstand extended periods

of service at high temperatures, but also must tolerate

severe environmental conditions, such as highly corrosive fumes from

a jet engine. In addition to the increased performance required

for aerospace applications, the performance demands for

land-based energy applications are also increasing. The traditional

approach for development of a new alloy relies on the knowledge

and experience of the engineer, which can be costly due to

the significant amount of testing required to obtain the

correct properties.

Two projects, the NIST-sponsored Consortium on Casting

of Aerospace Alloys and the DARPA-sponsored

Investment Casting Cooperative Arrangement, focused on the modeling

of casting processes. For these projects, the Metallurgy

Division developed phase equilibria subroutines, which used a

modified version of public domain software code, and constructed

a thermodynamic database for Ni-based alloys. On the basis

of these subroutines, programs were developed that

perform equilibrium (lever) and Scheil solidification calculations

for multicomponent alloys. UES Software, Inc., implemented

these codes into ProCASTTM, a finite element method

software package for the simulation of casting processes. The

original NIST Ni-superalloy thermodynamic database includes

9 elements, Ni-Al-Co-Cr-Mo-Re-Ta-Ti-W, and is based

on critically evaluated literature work and NIST work on

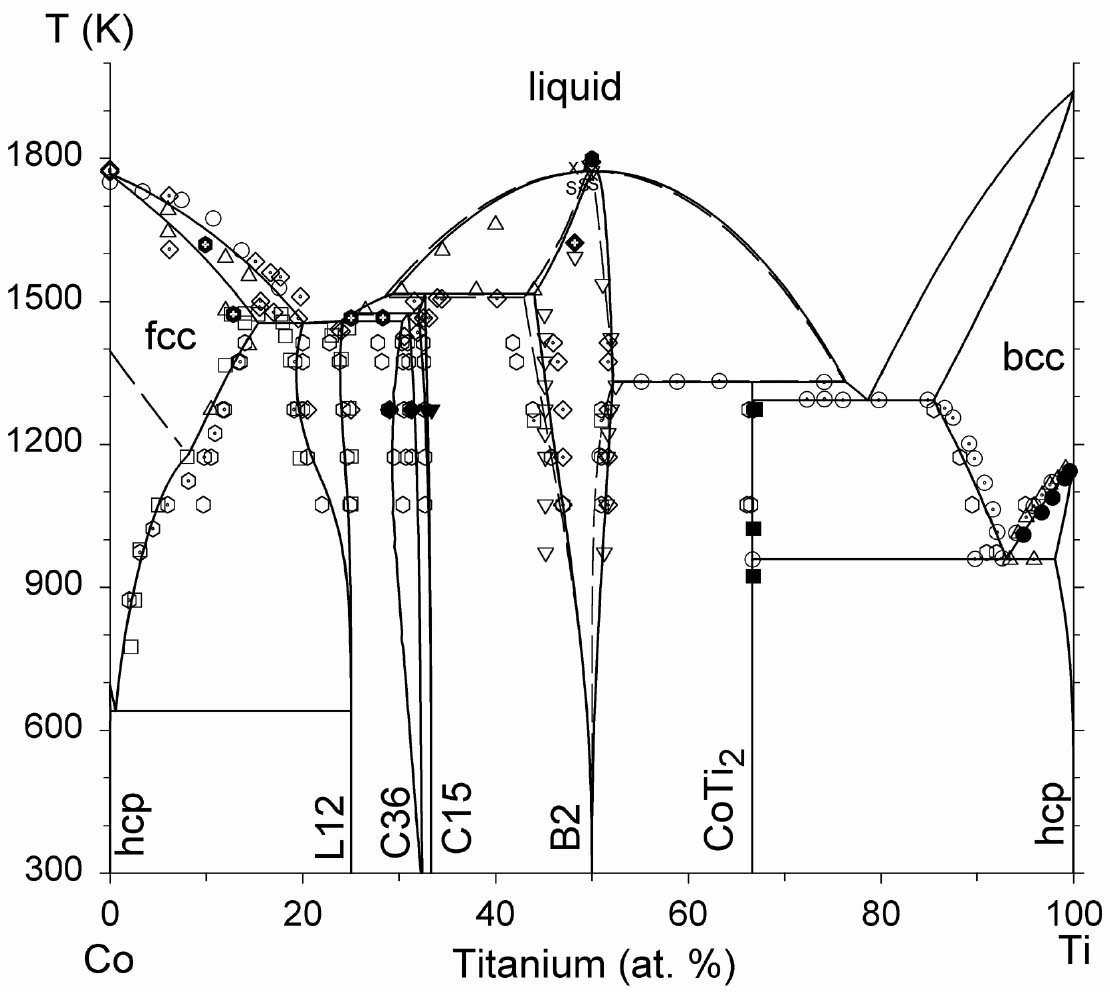

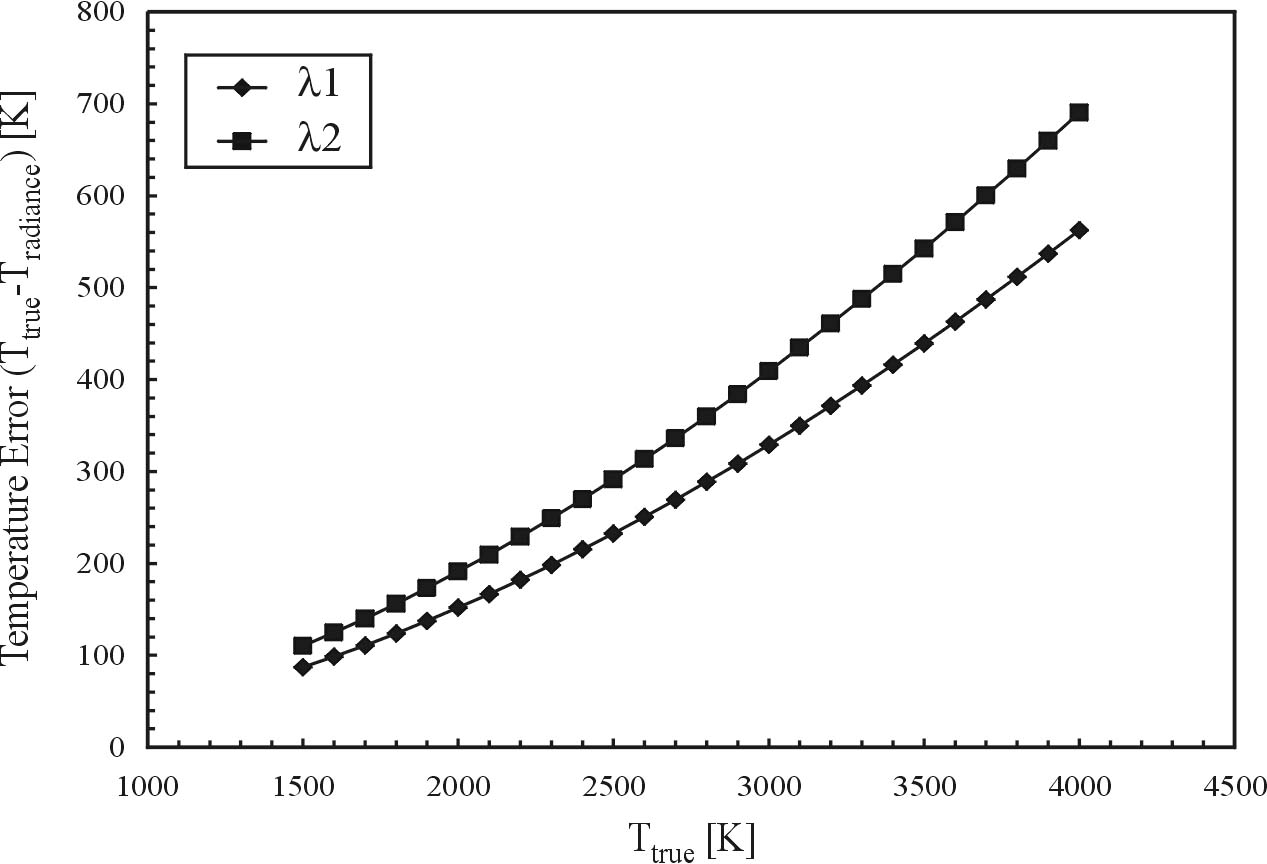

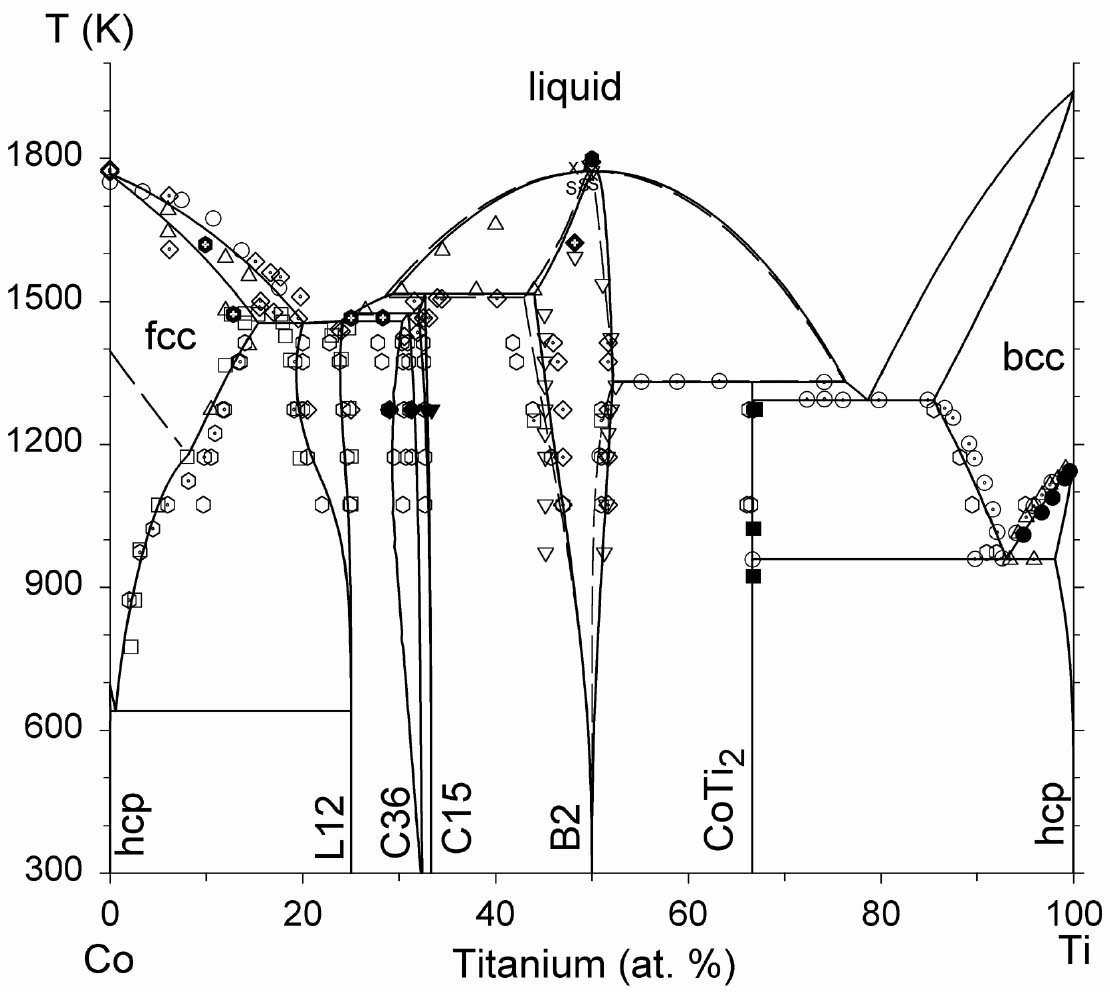

Co-Mo, Co-Ti, Co-Re and Re-Ti systems. Figure 1 shows the results

of the assessment of the Co-Ti system. This database includes

all known phases in this 9-component system. Recently,

the description of the liquid, g, and g' phases were expanded

to include Hf. Electronic versions of the NIST database have

been distributed to various industries, universities, and

national laboratories.

As a result of this work, the detailed solidification behavior

for Ni-base superalloys can be predicted. This has improved

the quality of solidification simulations for investment castings,

by providing more reliable predictions of casting defects, and

thus allows industry to eliminate the need for extensive testing

of many castings to reach an acceptable design.

In addition to a dependence on multicomponent

thermodynamics, a wide variety of Ni-base superalloy applications

are made more complex by diffusion processes, including

solidification, homogenization, g' precipitation, bonding and

repairing processes, and protective bond coats. Many of these

industrial problems can be addressed using a commercial

finite-difference diffusion simulation code that incorporates

composition-dependent diffusivities combined with

multicomponent

|

|

Figure 1. The assessed Co-Ti phase diagram

(lines) compared to selected experimental data (symbols)

thermodynamics. The first step in modeling these

multicomponent multiphase diffusion problems is the development of

a multicomponent diffusion mobility database. This database

is used in conjunction with the developed thermodynamic

database to calculate the composition-dependent diffusivities for a

given phase. As part of a General Electric-lead DARPA project

for Accelerated Insertion of Materials (AIM), NIST is developing

a diffusion mobility database for Ni-base superalloys. The

NIST mobility database can be used in conjunction with the NIST

Ni-superalloy thermodynamic database, as well as other

commercial thermodynamic databases.

The diffusion data in various constituent binary systems

have been assessed to establish this multicomponent

diffusion mobility database. The initial diffusion mobility database

is focused on substitutional diffusion in the g (fcc) phase for

the Ni-Al-Co-Cr-Hf-Mo-Nb-Re-Ta-Ti-W system. The

mobilities determined for the self-diffusion of the components in

the metastable fcc phase (where applicable) are consistent with

the well-known correlation of melting point and diffusivity.

The general agreement of calculated and measured diffusion

coefficients in the Ni-Co-Cr-Mo and Ni-Al-Cr-Mo systems

demonstrates the validity of the database for the extrapolation to

higher order systems.

The current diffusion mobility database has been

distributed electronically to various industrial partners who are

evaluating the database and providing additional experimental data

for further validation of the database. One such validation, which

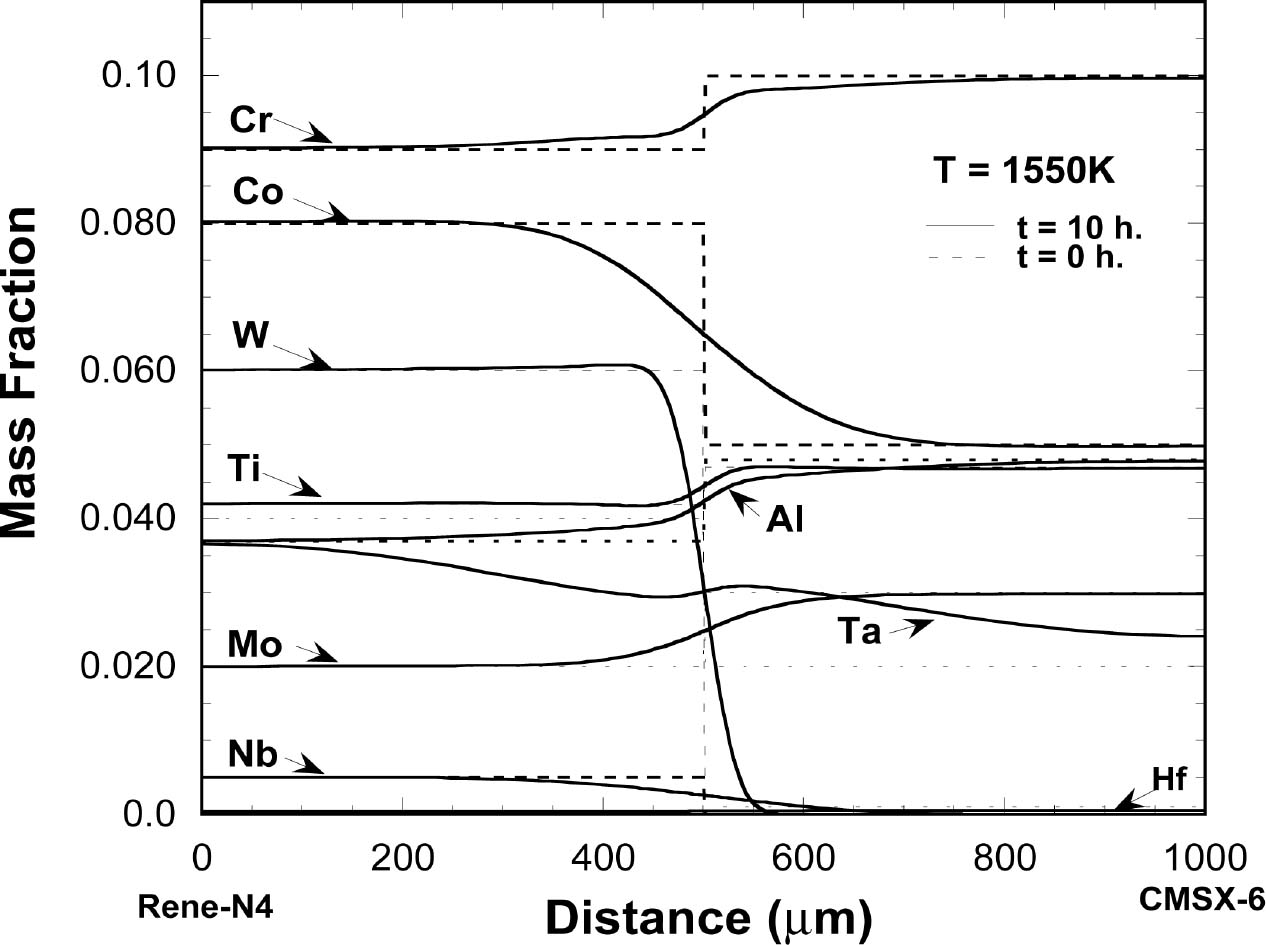

is in progress, compares the simulation diffusion profile

between two commercial Ni-base superalloys in the

single-phase g (fcc)

|

|

|

|

|

|

|

|

| Back to the top

|

|

|

|

|

|

|

|

|

|

|

|

Technical Highlights

|

|

|

|

|

|

region with experimental results. Figure 2 shows the

composition profiles predicted from a diffusion couple simulation

using the current mobility database.

Figure 2. Composition profiles predicted for a

diffusion couple of René N4 and CMSX-6 superalloys in the

single-phase g (fcc) region at 1550 K for 10 h.

In addition to the prediction of diffusion profiles

between commercial superalloys, an approach that combines

multicomponent thermodynamics and diffusion is being utilized

to determine the g' particle size and g' particle size distribution

that is obtained after solidification and heat treatment. Also,

diffusion simulations can be used to optimize the heat treatment

schedules for cast superalloys to avoid incipient melting while

minimizing cost. Further advancement of multicomponent

multiphase diffusion simulations includes modeling the diffusion in

the ordered g' phase and development of a more

user-friendly electronic diffusion database for public use.

NIST's work on multicomponent thermodynamics and

diffusion has been widely recognized by various forums including:

• The 1998 Award for Excellence in Technology Transfer by

the Federal Laboratory Consortium for "Transfer to

the Aerospace Industry of Technology Developed for use

in the Analysis of Advanced Casting Processes"

(together with other researchers from MSEL and CSTL) .

• The 1999 Department of Commerce Gold Medal and the

2001 TMS Bruce Chalmers Award were both bestowed on

W. J. Boettinger, partly for his work in

solidification research.

• The paper "Thermodynamic Assessment of the

Co-Mo System" was awarded the 2001 Alloy Phase

Diagram International Committee Award for outstanding

evaluation of phase equilibria data.

|

|

"The efforts of NIST researchers on the Cast Aerospace

Alloys consortium were instrumental in making solidification

science available to the foundry floor. Their efforts on developing

a thermodynamic database for Ni-base superalloys and coupling

it with solidification pathway analysis, thermophysical

property measurements, spurious grain formation studies, and

solid/liquid interface sensors have significantly increased our

understanding of solidification in the investment casing process. The

success of these activities is paving the way for additional

collaborations with important commercial benefit to Howmet."

— Boyd A. Mueller, Howmet Research Corporation

|

|

|

|

|

|

For More Information

On This Topic:

|

|

"Development of a Diffusion Mobility Database for Ni-Base Superalloys",

C. E. Campbell, W. J. Boettinger and U.R. Kattner, Acta mater,

in press

W. J. Boettinger, C. E. Campbell and U.R. Kattner (NIST/MSEL)

|

|

|

|

|

|

|

|

|

|

| Back to the top |

|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)